What a disaster...

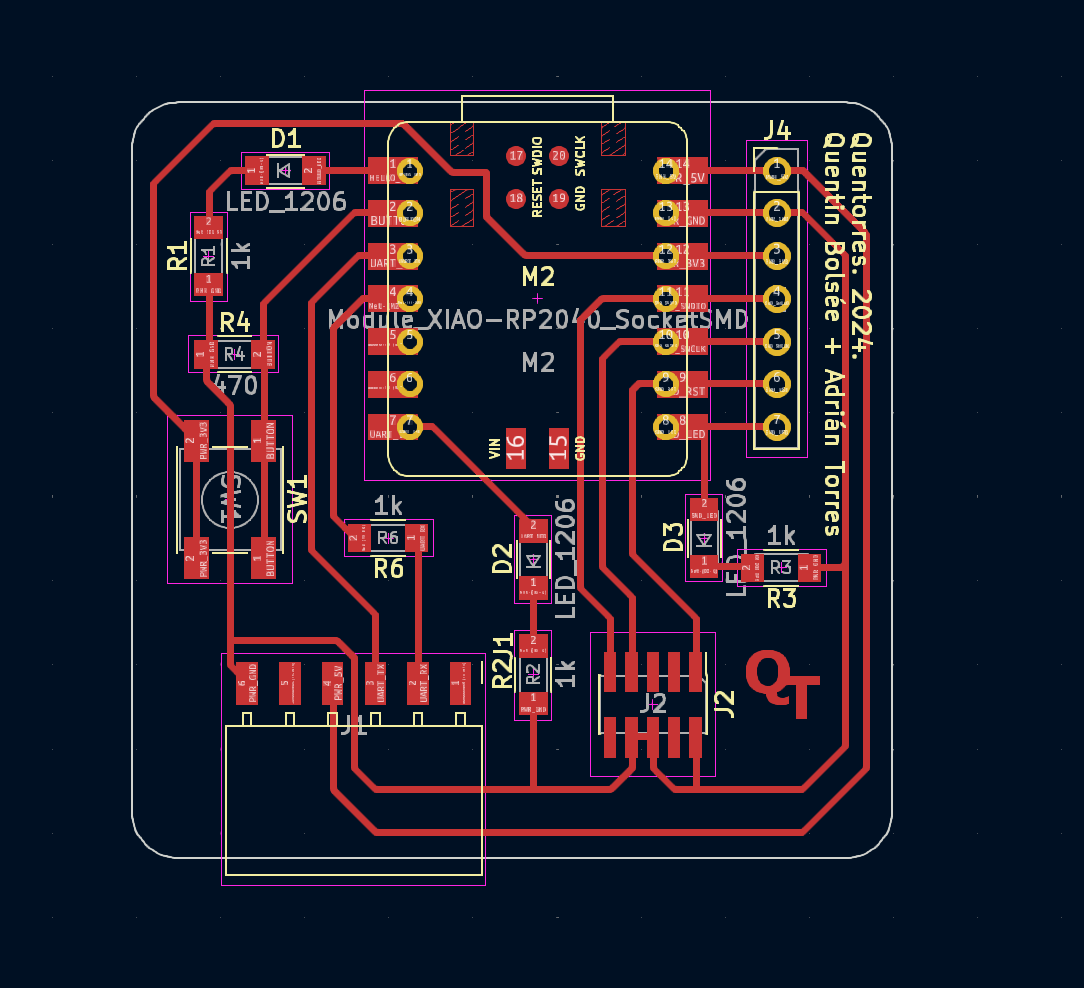

This weeks assignment was to mill a simple PCB and solder on the components to make it all work. Enjoy my story of trials and tribulations through one of the most frustrating assignments ever.

Part 1: The Quest Begins

Once upon a time, on the 24th day of September in the year 2024, in a magical land known as the DePaul IRL Lab 1, nestled in the vast city of Chicago, Illinois, on planet Earth, within the Solar System, in the Milky Way, a brave heroine named Leah Richerson embarked on an arduous quest. Her mission was to craft a mystical artifact, a Printed Circuit Board (PCB), using a most temperamental machine known as the Carvera.

But before the journey even truly began, a fierce dragon in the form of software awaited Leah. Its name was "MakeraCAM," a beast notorious for its cruelty and unpredictable nature. Leah, undeterred, sought to master its intricacies, but lo! It crashed time and time again, leaving her frazzled and frustrated. Days passed in this strange battle of wits. Every time she thought she had conquered it, aligning the drill holes for the PCB turned out to be a puzzle most vile, as if cursed by ancient forces.

Part 2: The Cursed Traces

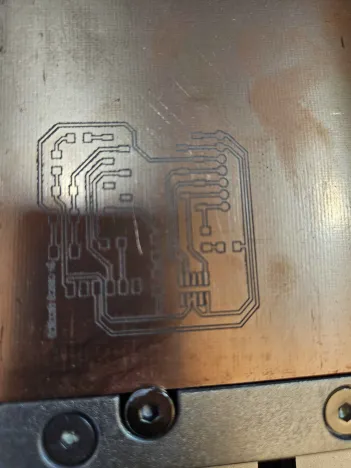

With great perseverance, Leah ventured forward, having gained a measure of control over the unruly software. Now, she stood before the mighty Carvera itself, ready to mill out the traces that would bring her PCB to life. But alas, the gods of the workshop seemed displeased with her efforts.

For six times—yes, six!—her board was thwarted by trials. Some were too shallow, others too deep, and the fiendish machine simply refused to level her board properly. Each attempt was more frustrating than the last, with the Carvera crashing just as Leah neared a breakthrough. Yet, Leah did not waver. She knew that with each failure, she grew wiser. The path to victory was fraught with obstacles, but her resolve was as firm as the sturdiest copper.

Part 3: The Solder Mask and the Silkscreen Fiasco

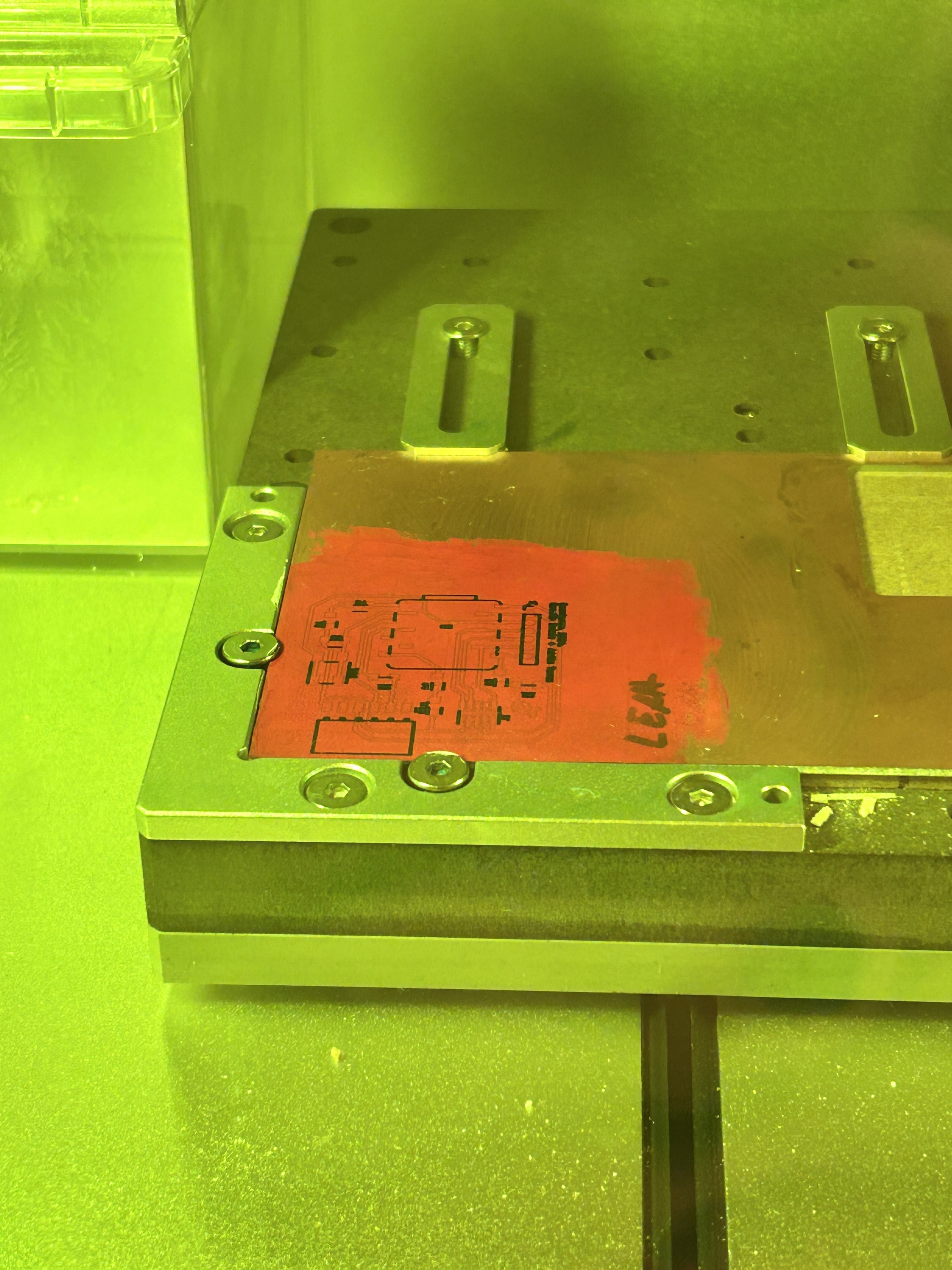

After many grueling battles, the traces were finally milled! The time had come for Leah to apply the sacred solder mask, and to her surprise, this task seemed almost a blessing—a rare moment of ease in her long struggle. The solder mask was laid with the precision of an artisan, and Leah could almost see the light at the end of the tunnel.

But peace was short-lived. The silkscreen layer, meant to mark the final details upon her board, awaited next. Leah, feeling a sense of accomplishment, began to apply it—but as fate would have it, the second Carvera machine, required to laser cut the silkscreen, was out of commission. Forced to wait for what felt like an eternity (or about 20 minutes in mortal time), Leah bided her time, her patience wearing thin.

Finally, the Carvera was ready to be used again. But when the silkscreen was cut, it was misaligned, as if tricked by some invisible gremlin. Leah groaned, realizing this part of the journey had gone awry. The silkscreen, meant to shine in elegant precision, now stood crooked and wayward.

Part 4: The Final Steps to Victory

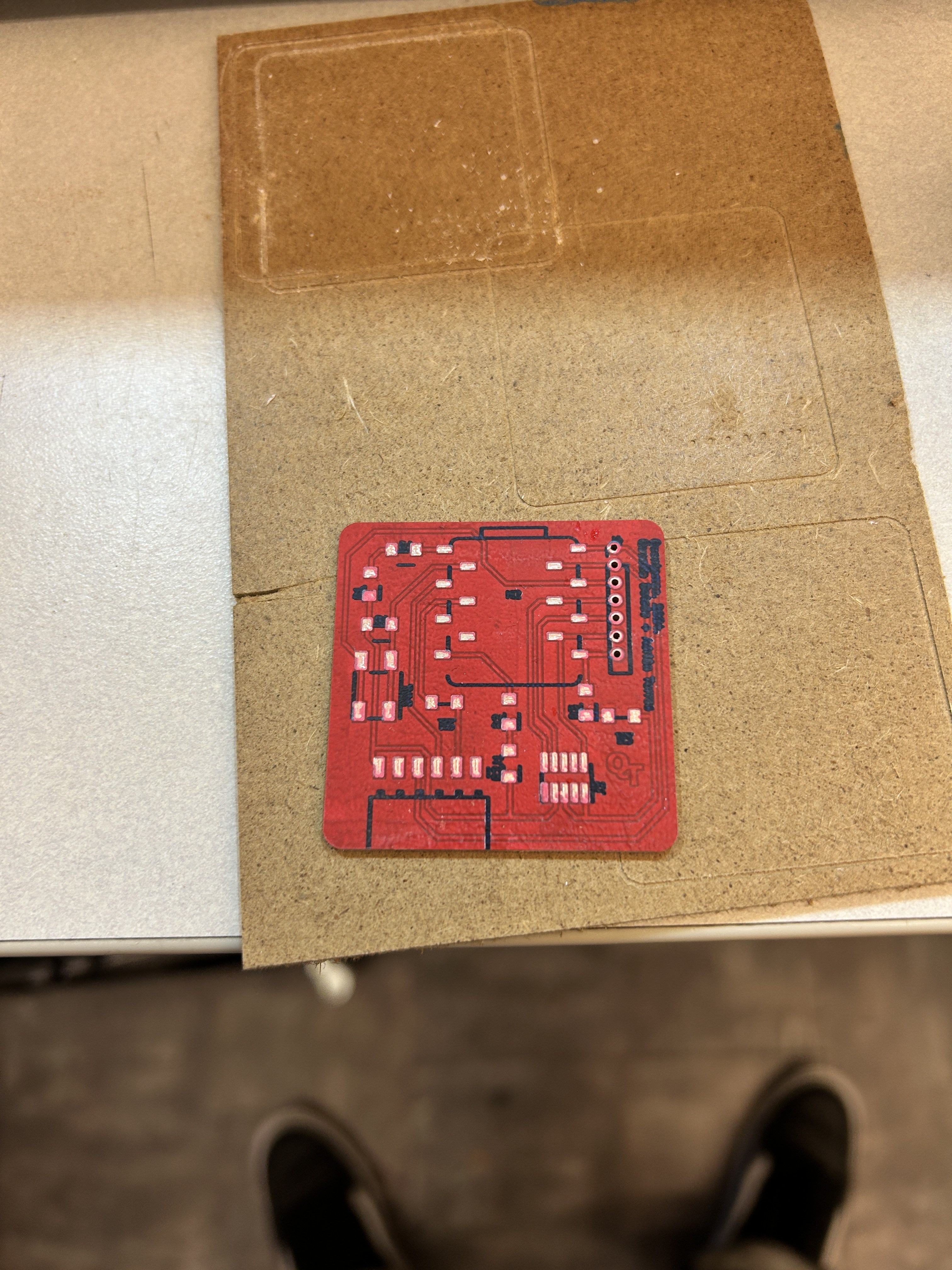

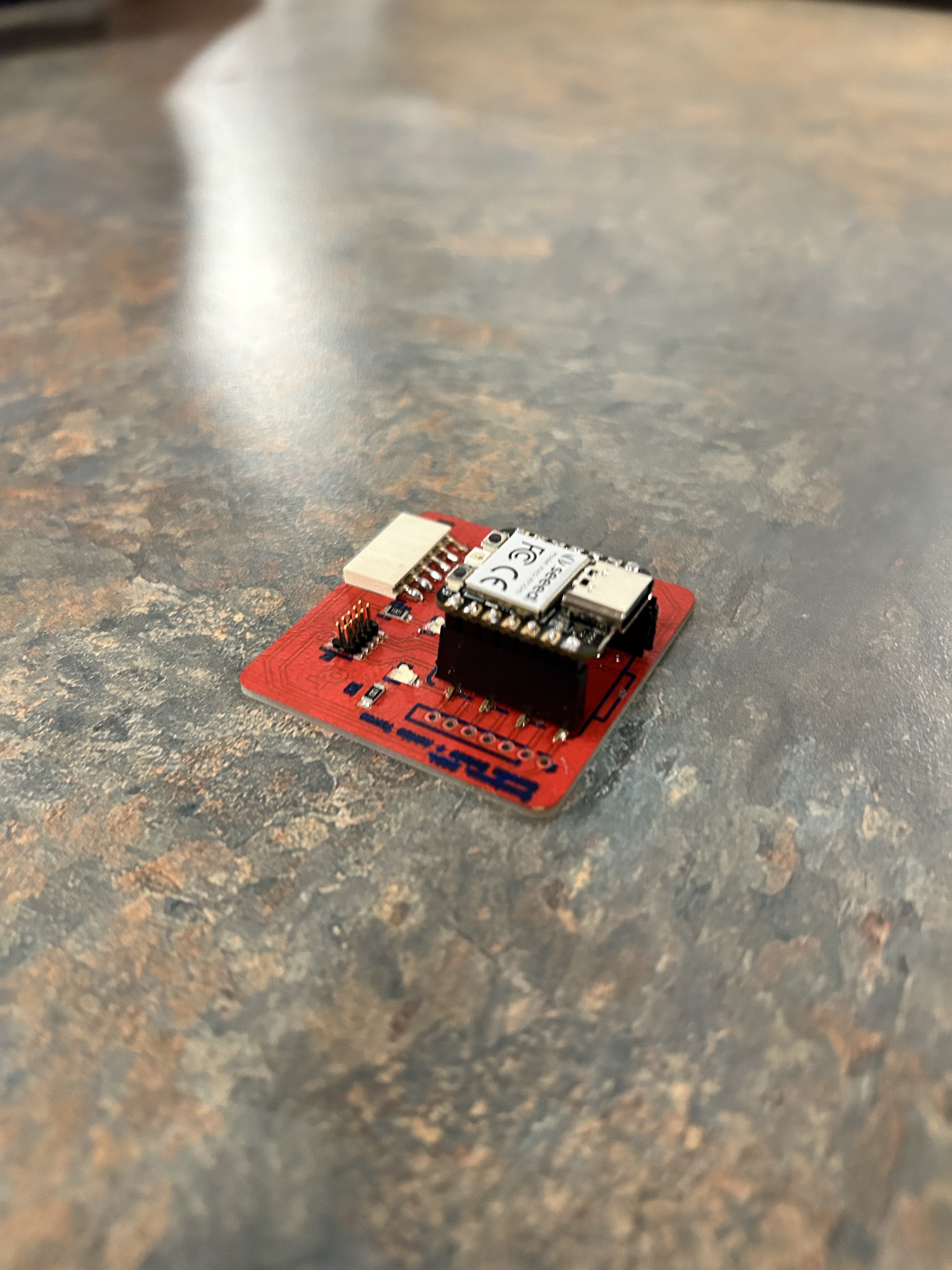

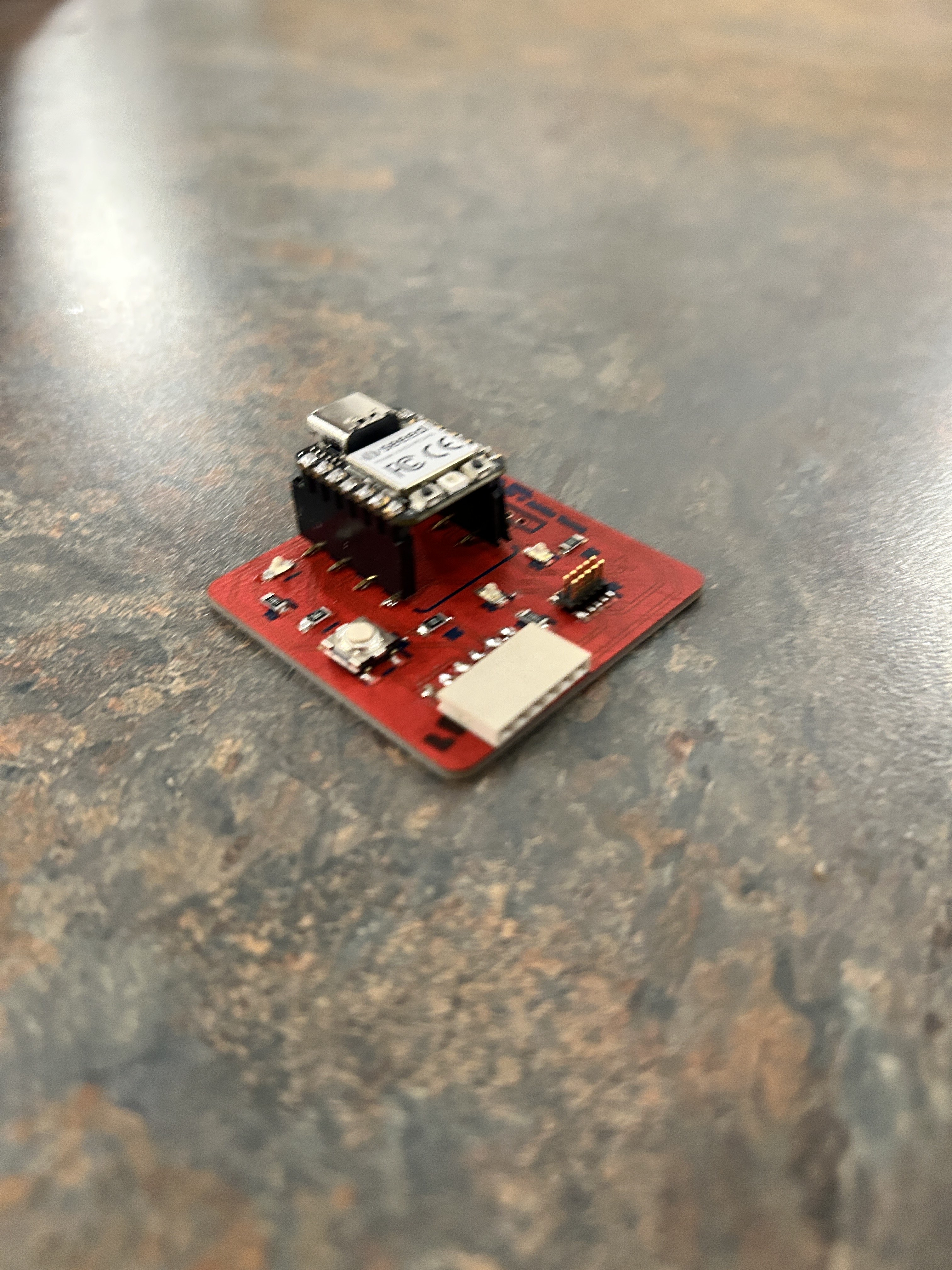

Though disheartened, Leah pressed on. There was no time to dwell on misaligned silkscreens, for the next trial was drilling the holes and cutting out her board. Thankfully, this part of the adventure went relatively smoothly, as if the forces of the universe had finally taken pity on her struggles. The Carvera hummed, content for the moment, as the final cut was made. Leah now held in her hands a PCB almost ready for its final transformation.

Instead of wielding a soldering iron, Leah turned to the ancient and powerful technique of soldering paste. She carefully applied the paste in precise spots, preparing for the components to be laid down. Each dab of paste held the promise of a perfect connection. With great care, Leah placed each component onto the board, aligning them with the markings of her design.

The final step involved a mystical device known as the reflow oven, a magical contraption that lay on a conveyor belt. As Leah gently placed her board onto the belt, she watched it slowly move through the oven's glowing chamber. The reflow process was like a timed ritual: the heat would rise, melting the soldering paste just enough to fuse the components to the board in perfect harmony. It would take about five minutes to complete the journey, but to Leah, it felt like a lifetime.

With each passing moment, her heart raced as the board inched its way toward the end of the conveyor belt. Finally, the reflow oven’s spell was complete, and the board emerged from the other side, the components perfectly soldered, gleaming with a fresh, metallic glow.

Leah retrieved her creation, inspecting it with awe. The reflow process had worked flawlessly, and her components were now firmly bonded to the board.

Part 5: The Hopeful End

With her heart full of hope and a completed circuit board in hand (hopefully), Leah had conquered the final trial. The DePaul IRL Lab 1, full of unpredictable magic and mechanical challenges, had tested her at every turn, but she emerged victorious.

And so, Leah’s tale of PCB milling, soldering paste, and conveyor-belt reflowing came to an end—for now. More challenges surely lay ahead, but for now, she could rest, proud of the marvelous creation she had crafted with her own two hands.