Fusion360 Fitting Parts Project

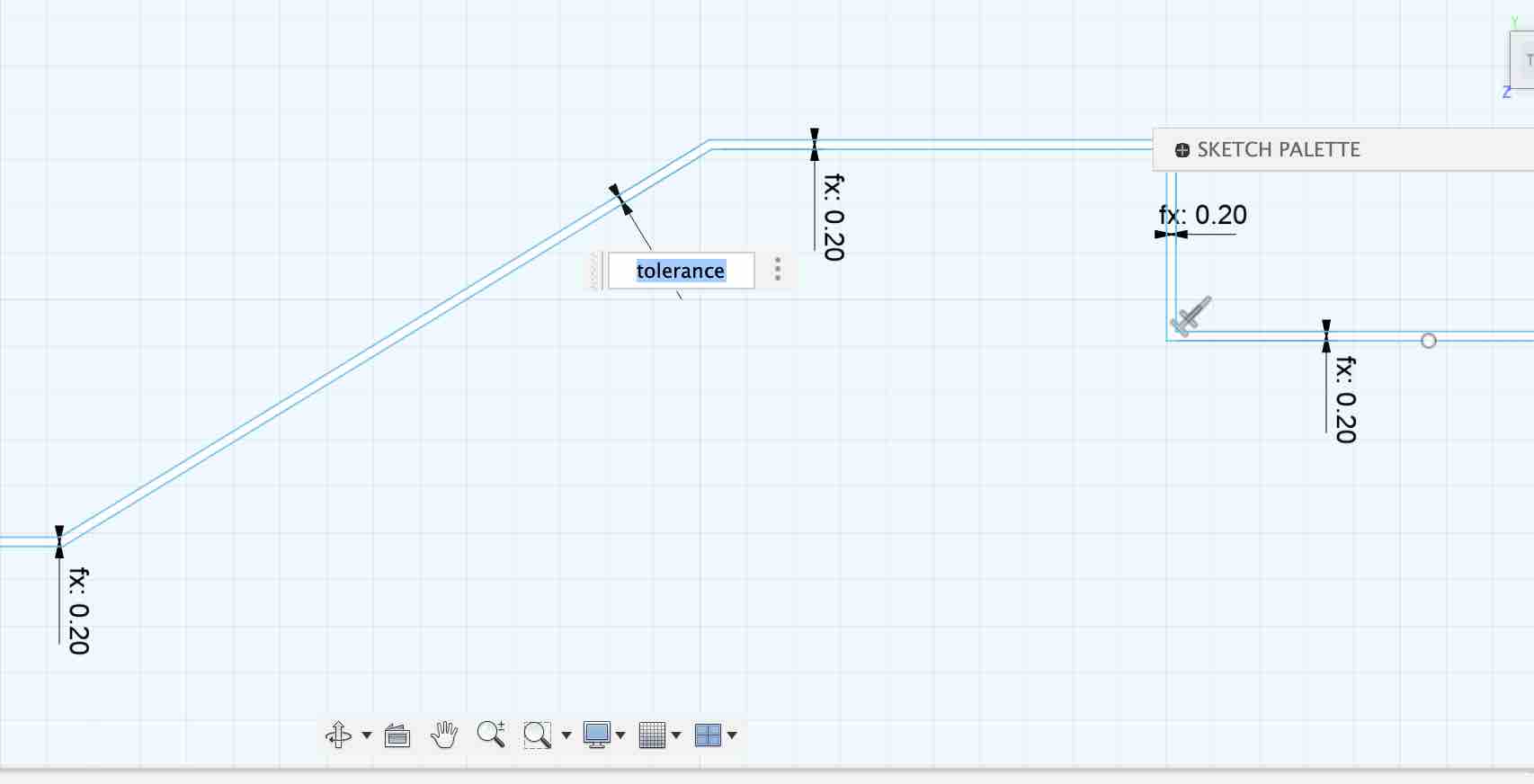

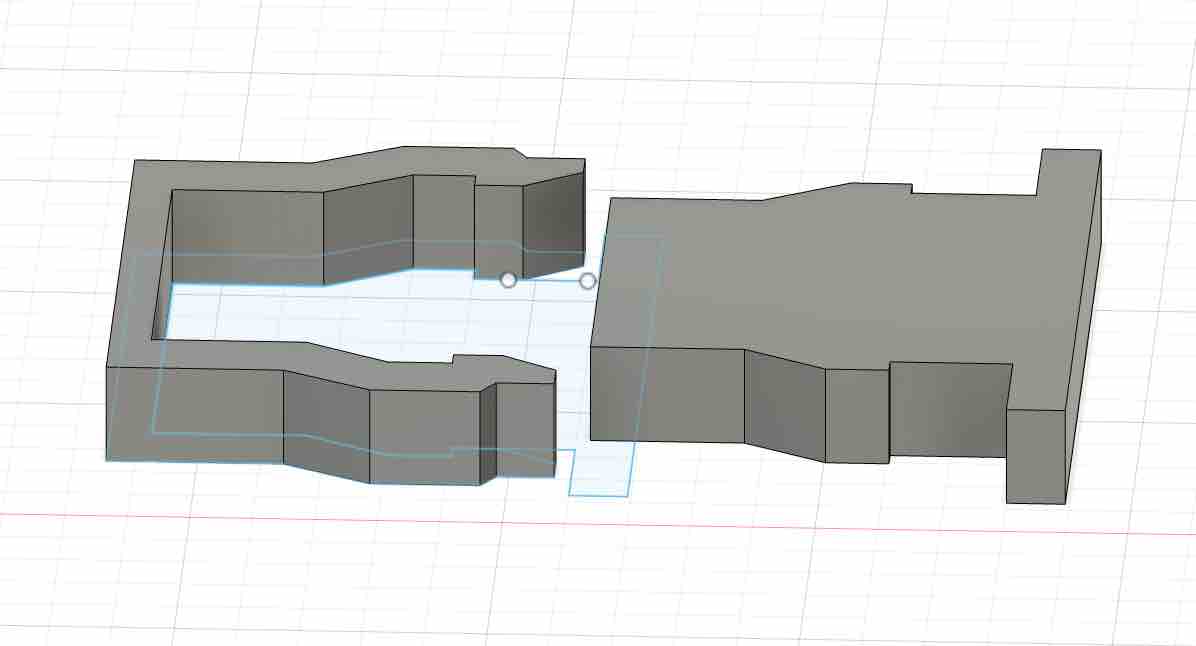

This project is one of the first we were assigned for class. The goal is to learn the basics of using CAD software by creating two simple parts that snap together with modular tolerances.

It was difficult for me because I'd never used a CAD software before, but after completing the project I feel as though I have a firmer grasp on it.