attached are some thoughts and tips for the work done this week.

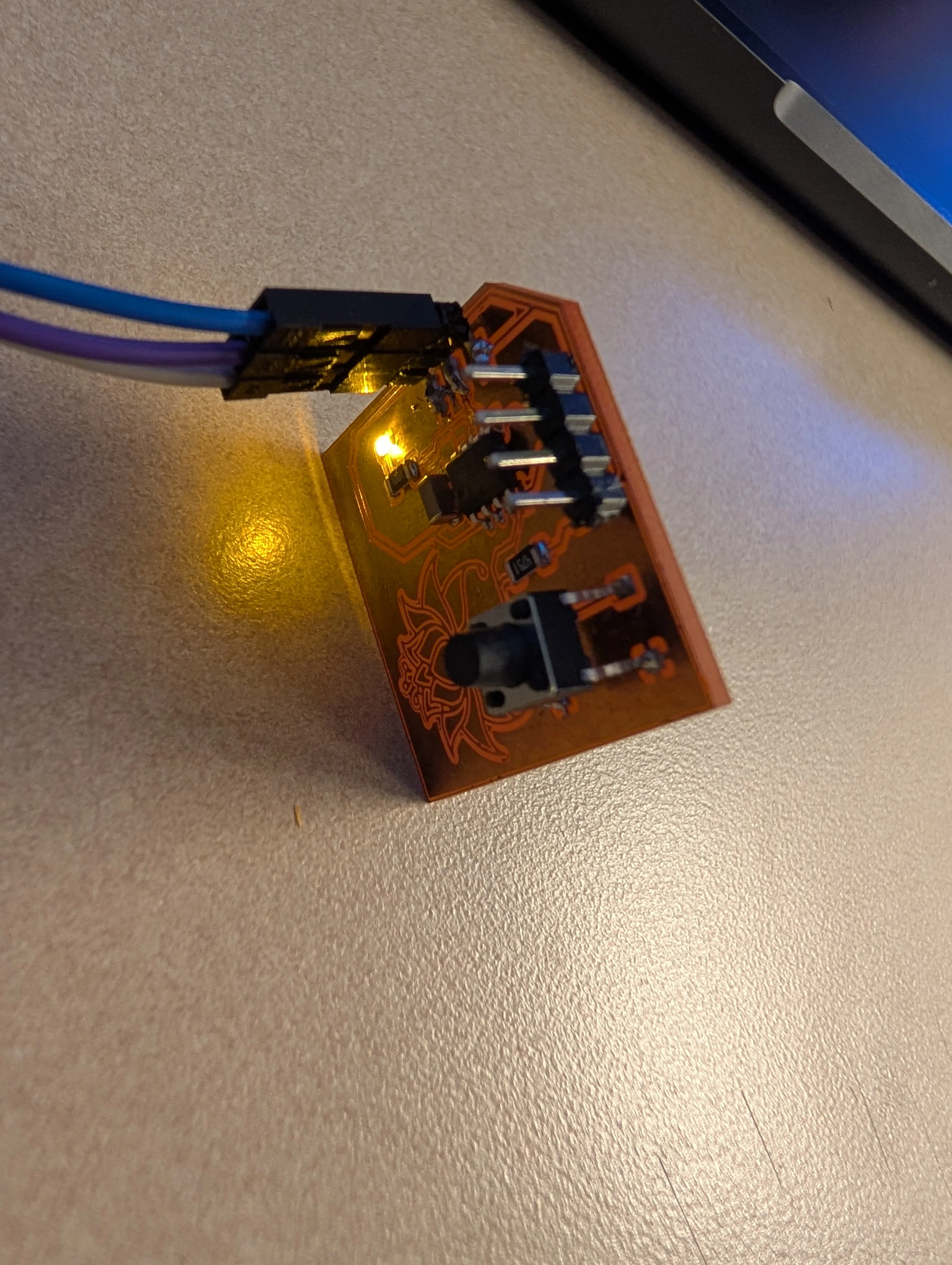

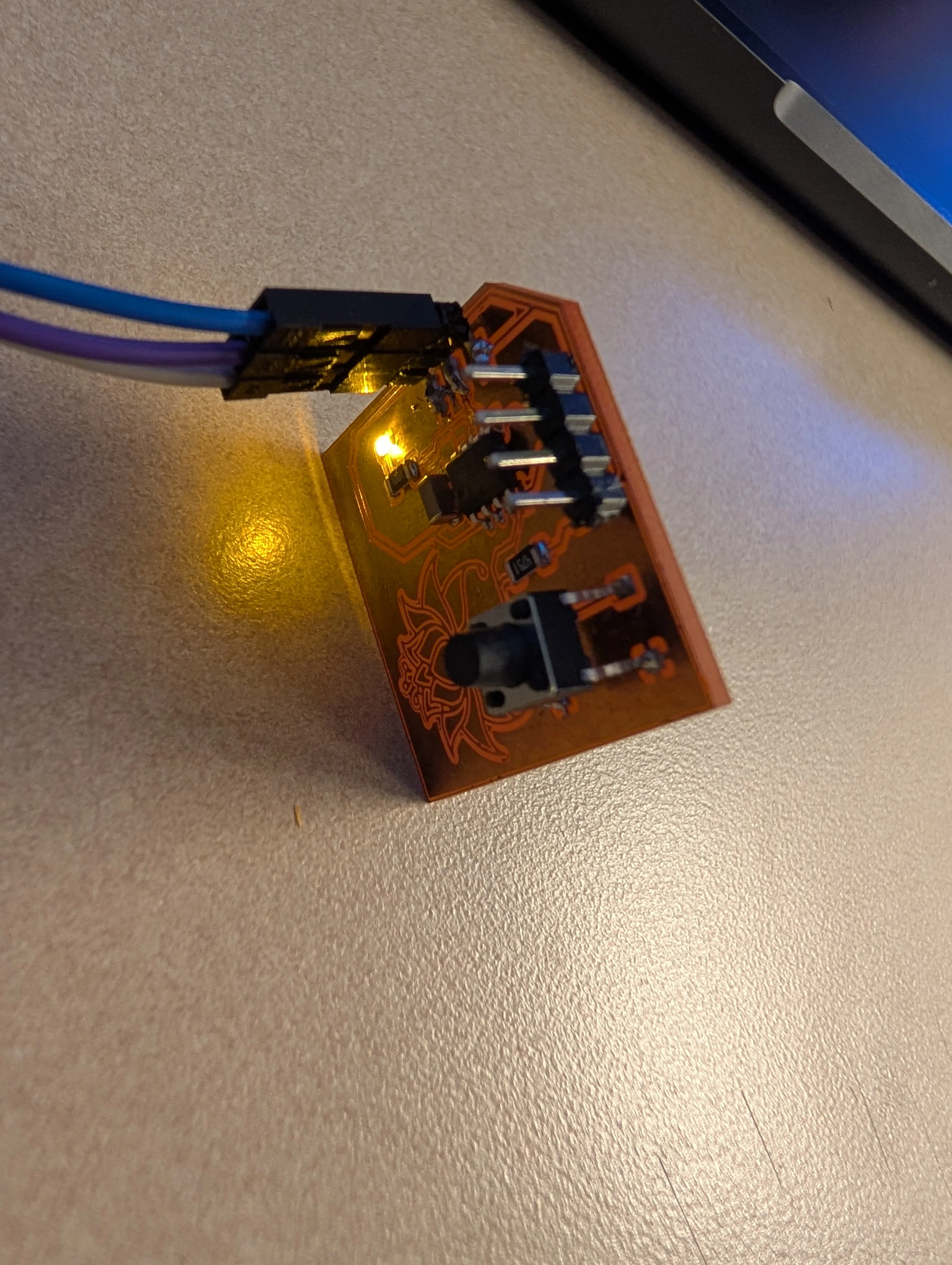

I had to debug at some point and the traces were too thin to use jumper wires I tried 0.4mm before and it was easier to debug not sure about 1mm, that sounds quite wide

I only needed to debug because the carvera corn bit'd my trace in the corner. if it wasn't a bad cut, the traces should be okay the pads are where the solder needs to go. These footprints were a bit small. Coming in early is good, it's better to have cold solder paste. Warm solder paste is runny and releases too much paste for such small pads--you need to do more work to split the paste that comes up or play around with the pressure. Warm paste also kinda starts flowing the paste out of the needle like a siphon. It's a mess, definitely use cold paste--more control. ^if you can, of course

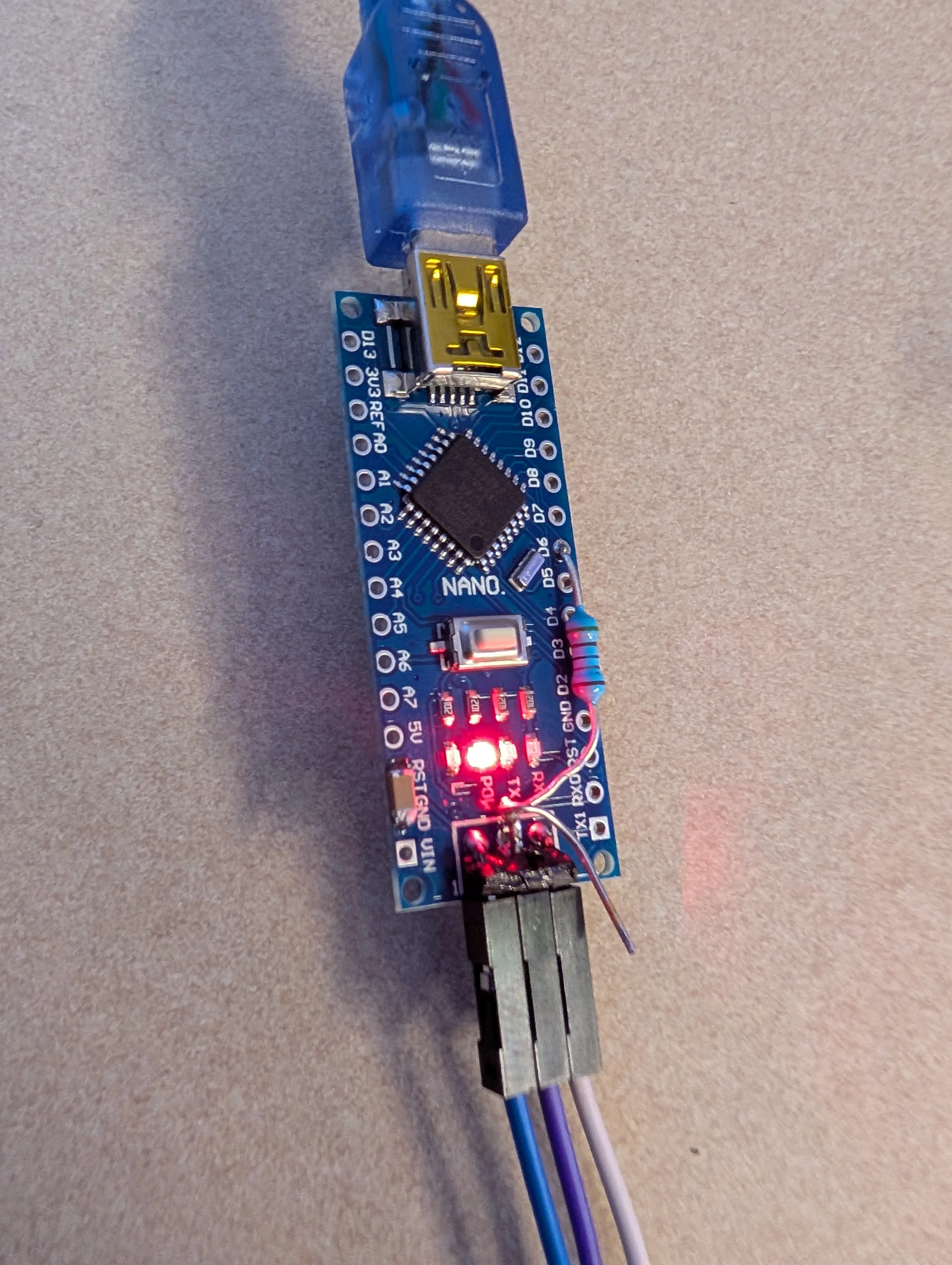

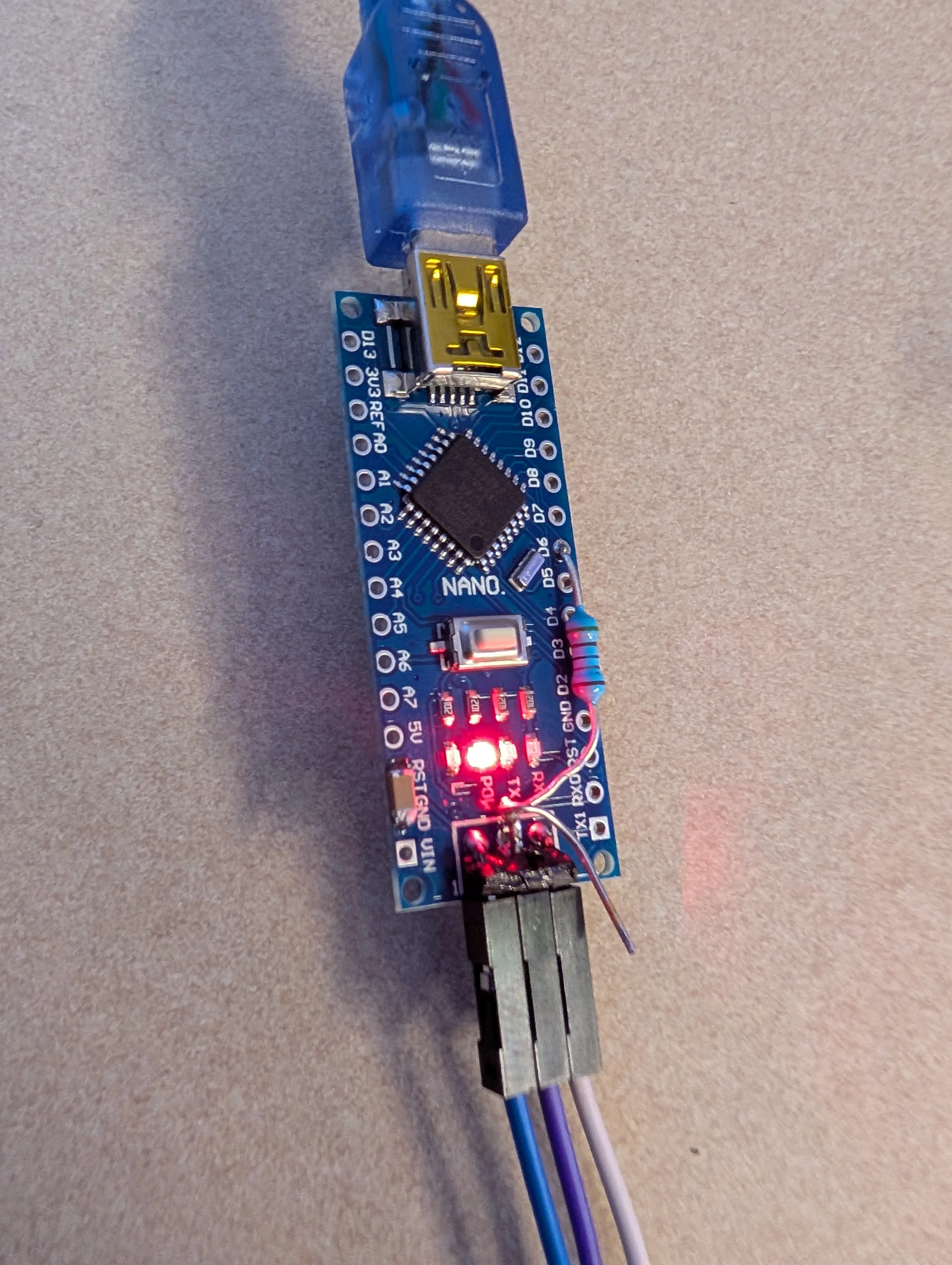

with a working board and nano, the Arduino IDE should be smooth sailing. David made a text guide in announcements of the forge discord specifically for the laptop stuff. The other part of this assignment is... making the working board. Do your best to make the board. If you finish while having no reason to doubt it'll work, then it's very likely you have a working board. Check continuity all the time. Firstly right after you clean the board, then again after you put solder paste on each pad (before putting SMDs), then again after you place SMDs on the solder paste, then again after it's baked in the neo den, then again after you hand solder any pins, then debugging is just more continuity testing until the board gives you no reason to doubt it (based on what you wanted from your schematic, and what you need for your project--the one which uses this PCB).

between any of these steps if it doesn't work, bring out your tweezers, wipe them on a napkin, then clean it out. or some alternative that works for you. The copper is all in position already. Continuities in the wrong places happen when the board isn't cleaned, both from copper dust/"noodles" that were milled, and from solder that bleeds to unintended traces/pads. noodles are thin copper lines that corn between your traces when the engraving bit does a shallow, not deep mill. If these copper lines are too thin they might break and mess with continuity. You can break them with a nudge by tweezers. Then, you can clean them like other copper dust/solder.