I'm still not sure what I want to do with my website.

It's a little frustrating to still be looking at a white background.

I want to make something that spells me out.

I started staying in the IRL more often.

It felt like I had more time this week than previous forge weeks.

I'm confident I have enough time now; How do I make the best use of it?

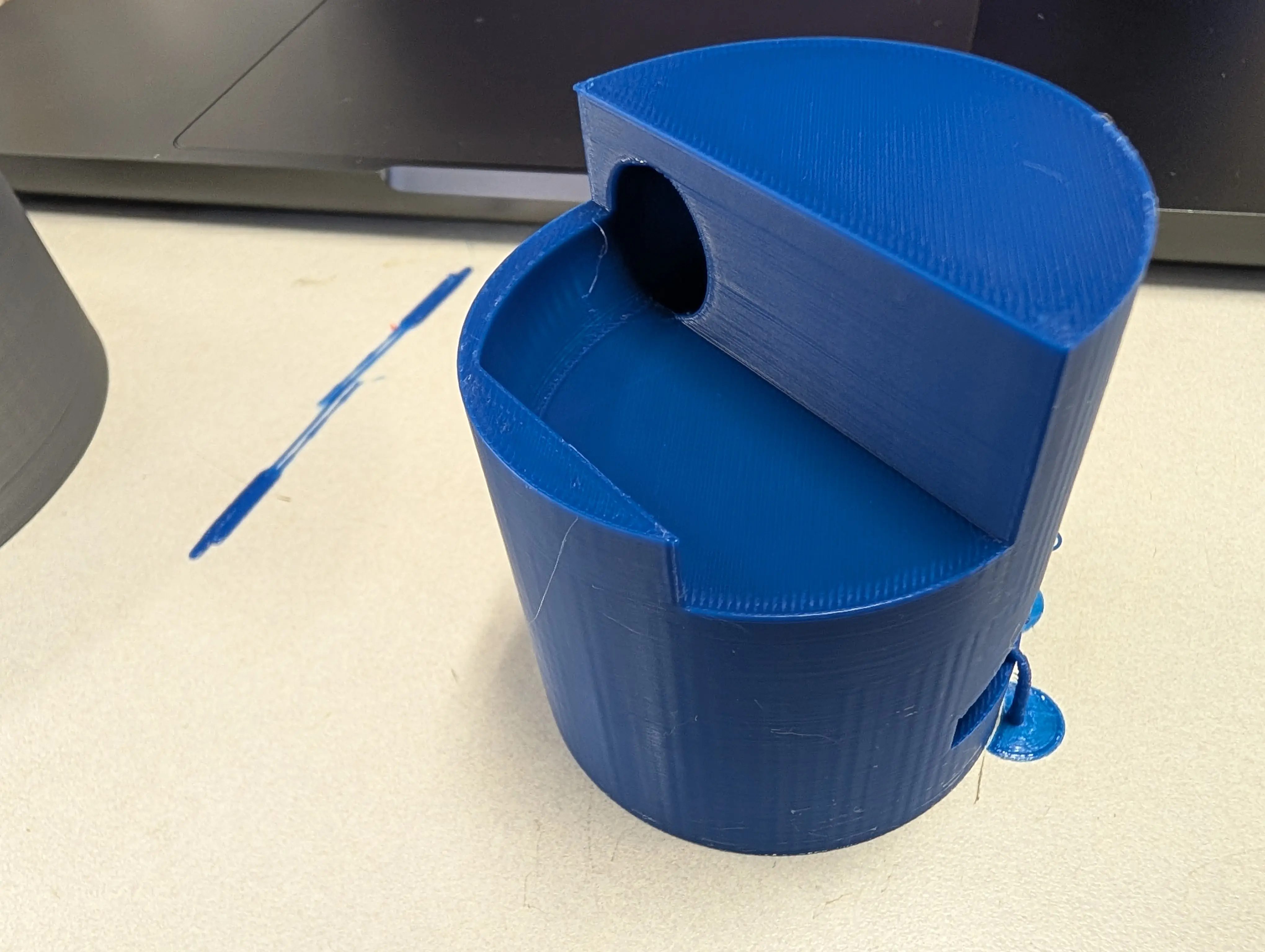

I made a helical chute for a marble to slide down.

This design can't easily be made by subtractive manufacturing processes.

Last school year I had created a marble maze as my final project for one of my courses.

I wanted to revisit that project.

Back then, I only knew the laser cutter and I was limited to cross sections of stock material to create the maze.

I wasn't experienced enough to use cross sections at the time. During the forge, I experimented with laser cutting cross sections.

Now, I wanted to try doing another thing I couldn't do before: 3D printing a maze with different elevations, connected by ramps and chutes.

I ran into some trouble though. The marbles I had were too big and the printers were too small.

I couldn't 3D print a complete maze without taking an exuberant amount of time.

Even accomodating normal size marbles meant that my prints would take up most of the printing space.

I decided for now that I'd try to at least experiment with height differences.

I played around with coils in fusion. Let's just say, I'm not easer to try them again. I might stick with lofts.

Eventually I got them working (as you saw above), but they're complicated and don't do what I want them to do.

For anyone trying to use coils: don't.

Well, to be fair, you can make them work.

I wanted a cut through my object in the shape of a helix with the top and bottom openings to be tangent to the plane they connect to.

This is the situation:

Fusion360 lets you move coils around as solid bodies, but coils can also cut through existing bodies.

Cuts cannot be interacted with, therefore you can't position them the same after creation like you can with solid coils.

Coils meant for cutting

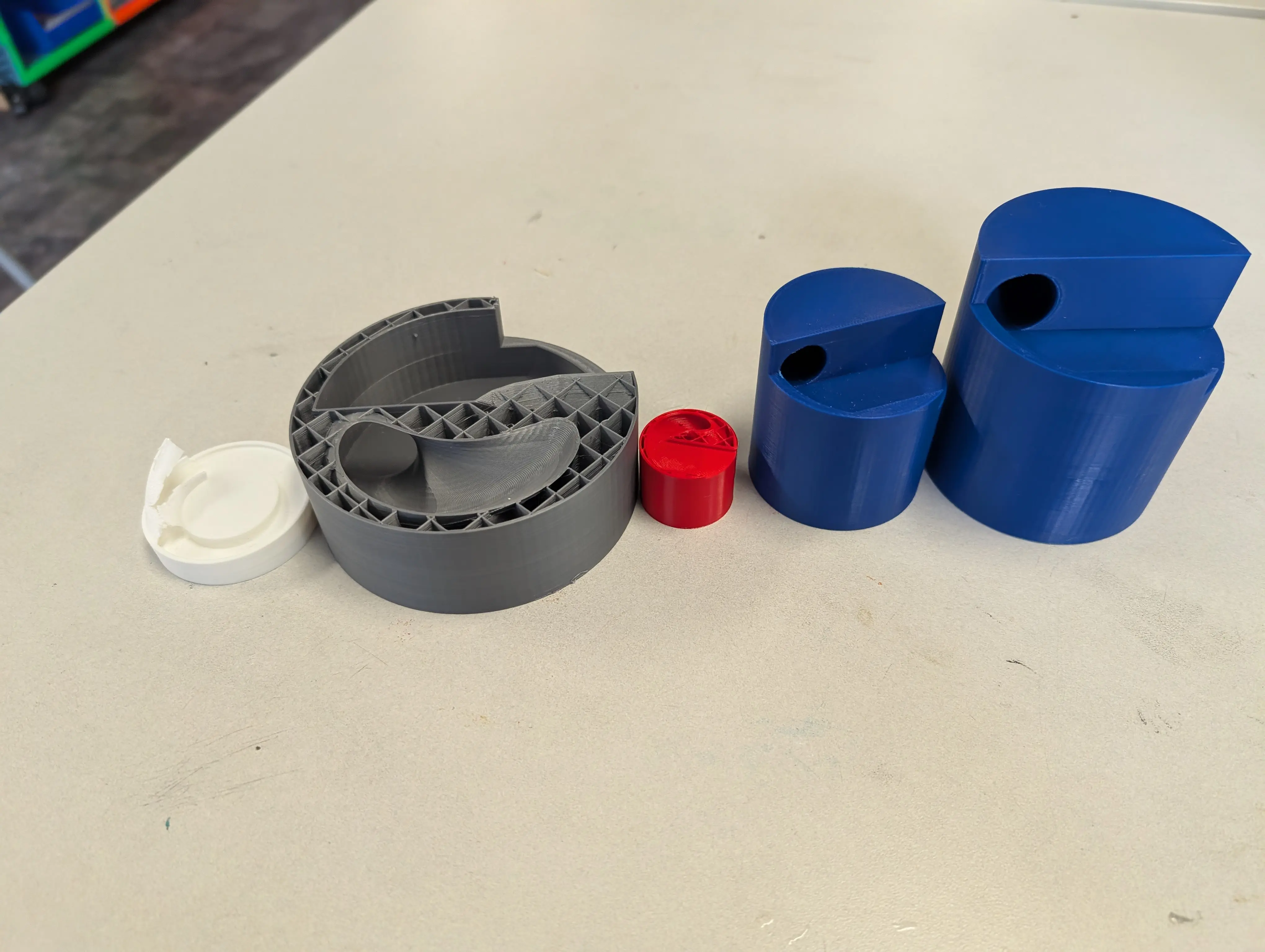

So... my successful print was actually my 5th print for this project.

(I had done a total of 7 prints this week. The two other ones were from a bonus project I'll talk about later).

I started with a small test. I wanted to try creating a small goal stand simliar to the ones in Super Monkey Ball 2 for the gamecube.

It worked! but, it easily broke off

The last print was too small, but I learned that I could use coils for ramps and tunnels!

Next I developed a cylinder shape. I wasn't satisfied with the exposed arch, I wanted to make it a tunnel.

I made it too big :|

I made it too small :|

I made it just righ-...

My marble got stuck again :/

Okay, this time I got it right.

The design didn't change between iterations, just my approaches to using BambuStudio and handling the 3D printers.

At the beginning of this page, I put my little guide to 3D printing.