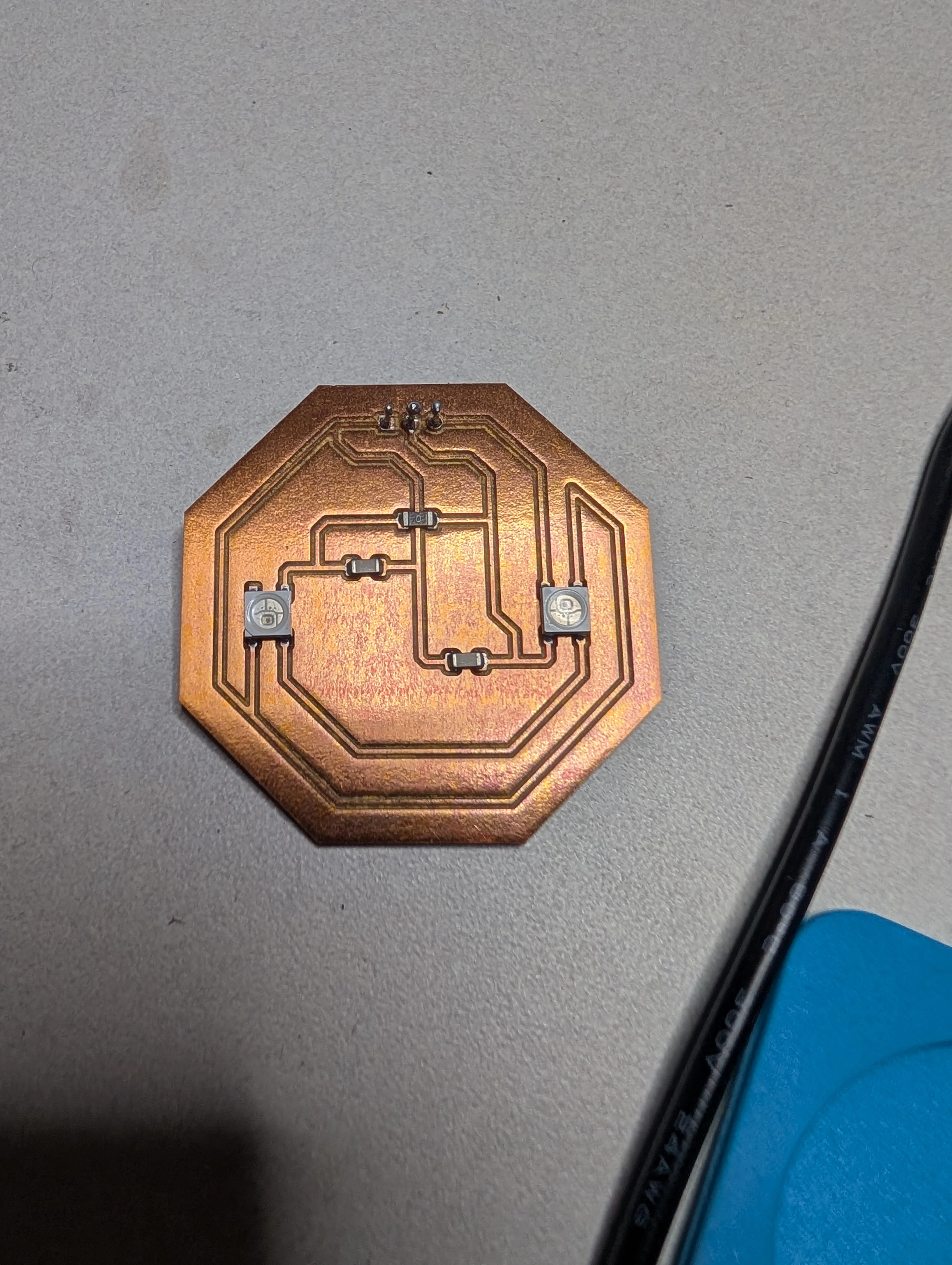

I started this week by refactoring my approach to the Forge.

People's projects are incredibly impressive. Beyond expectations.

I feel that I need more time. I need to give myself more space to not rush my decisions.

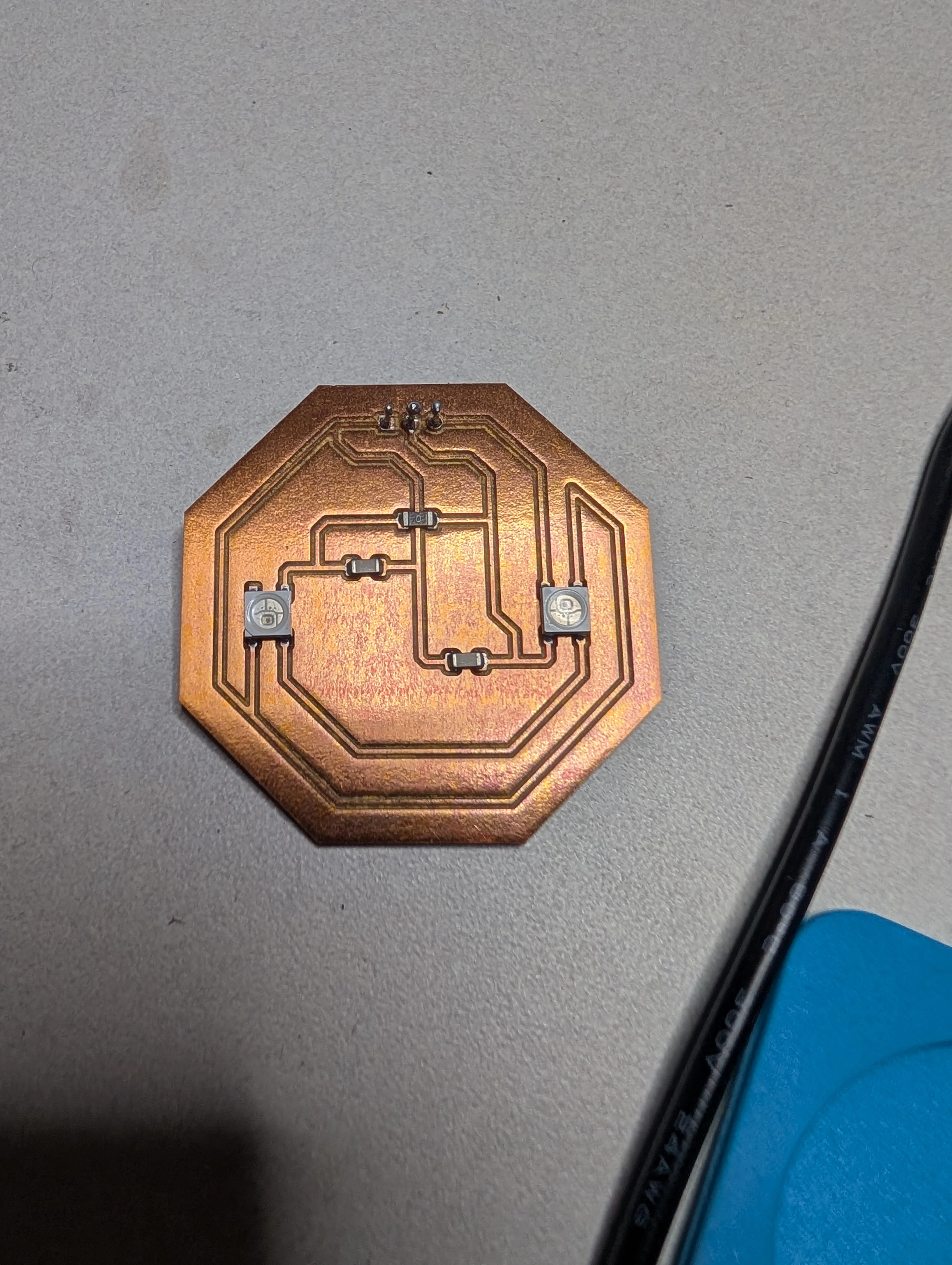

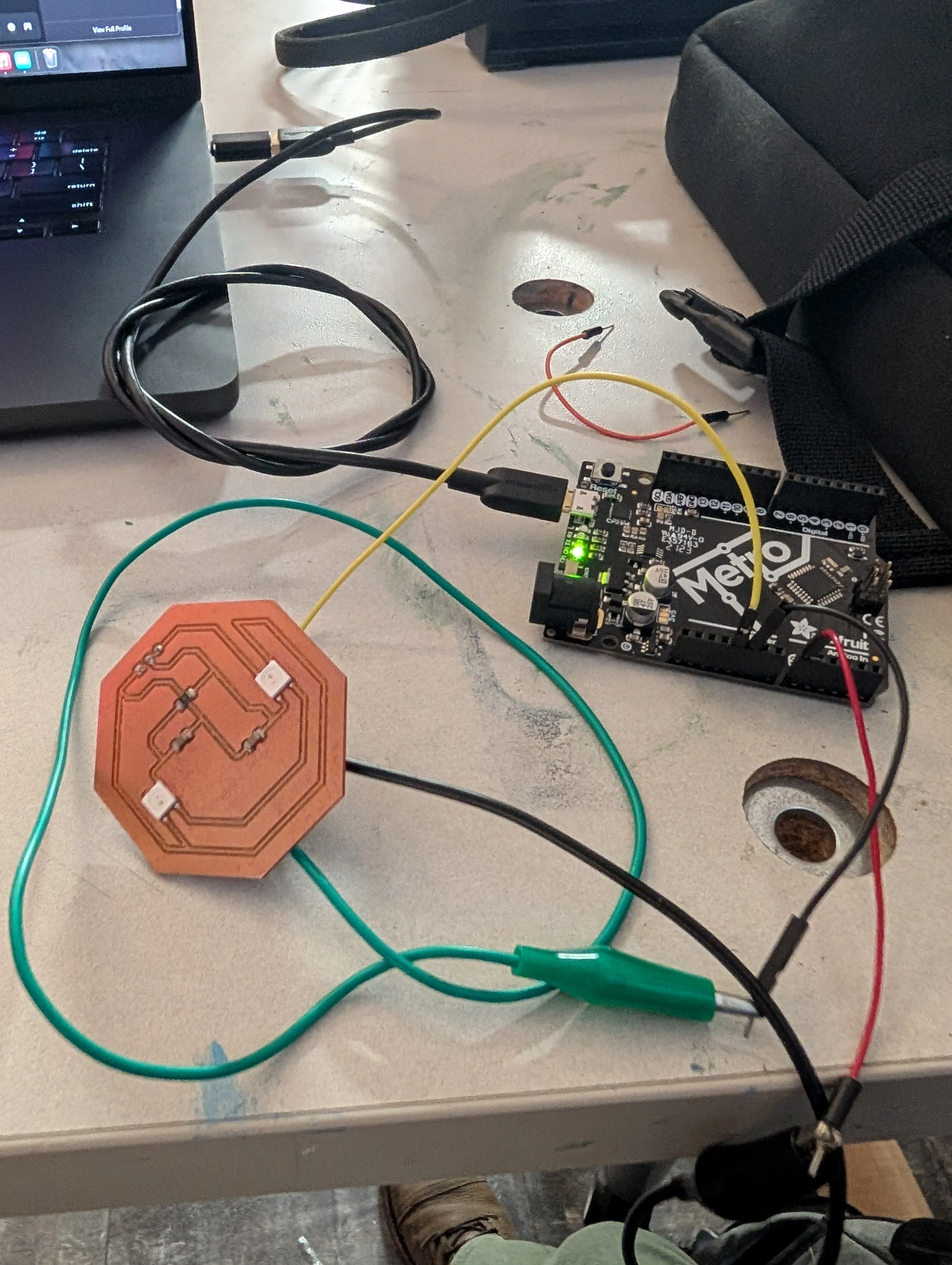

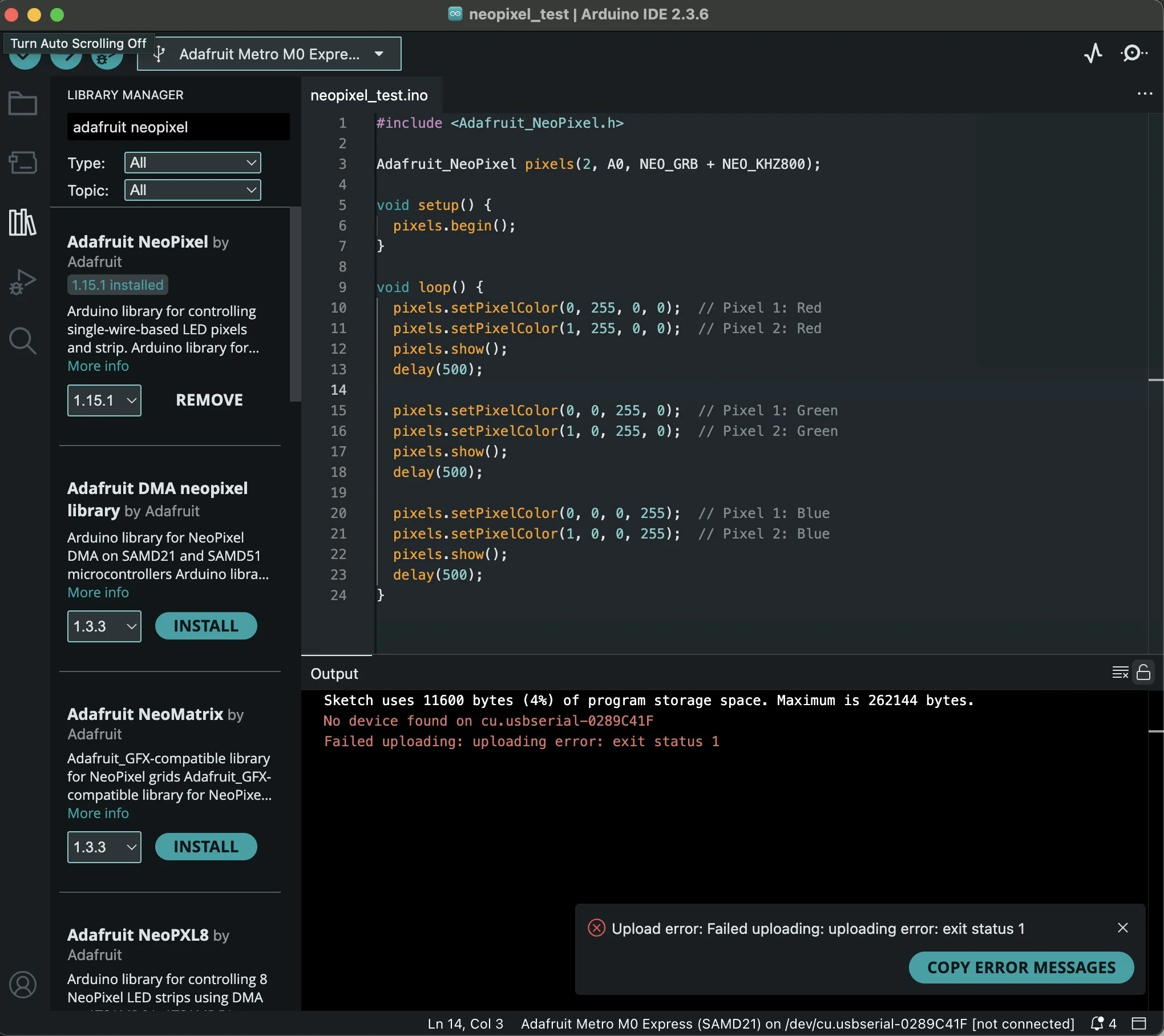

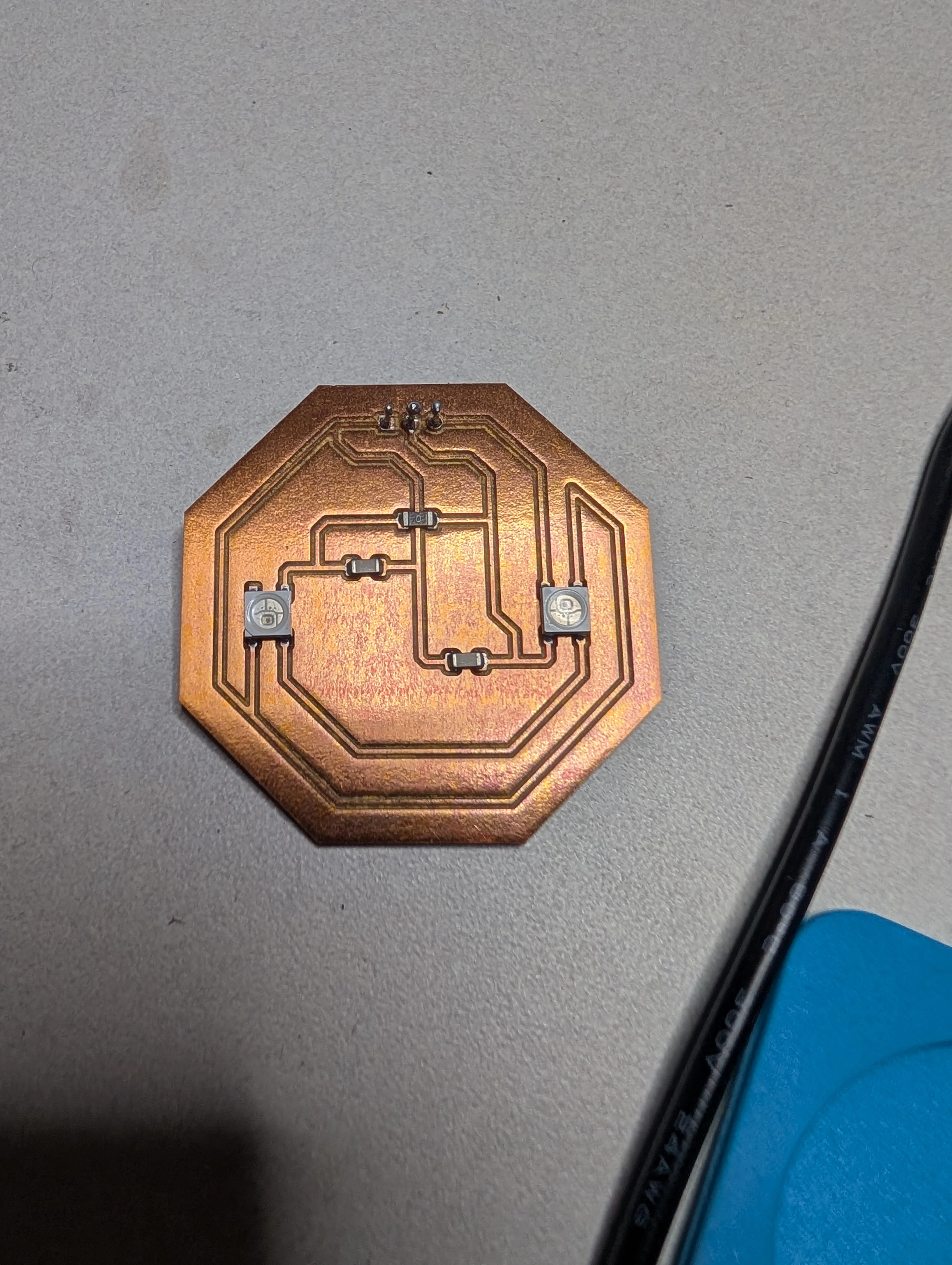

I made a PCB that includes two neopixels.

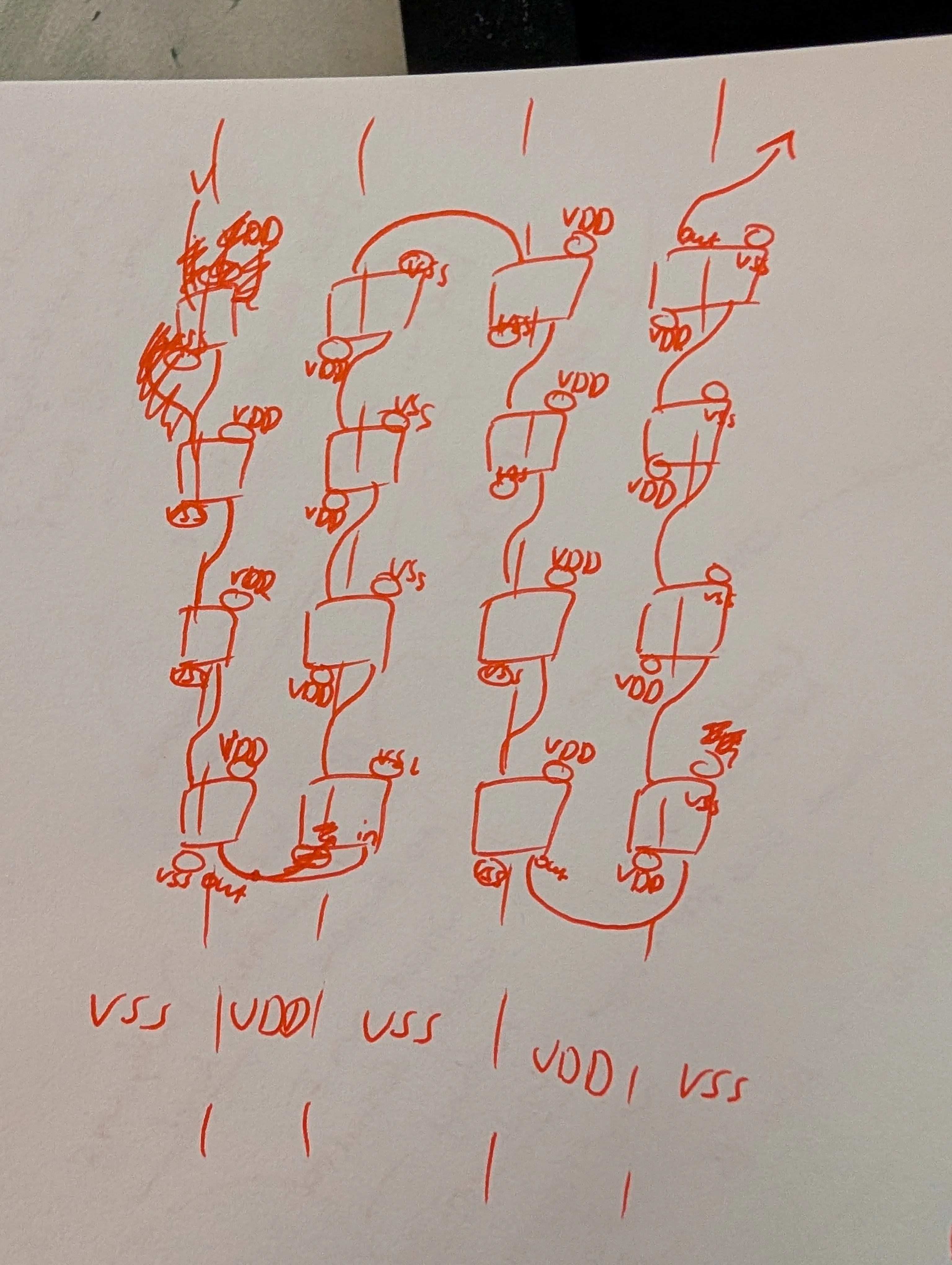

I tried to use neopixels for the week 4 project. I was curious about wiring 16 of them.

I made an attempt to wire them together and simplify the wiring by following the datasheet.

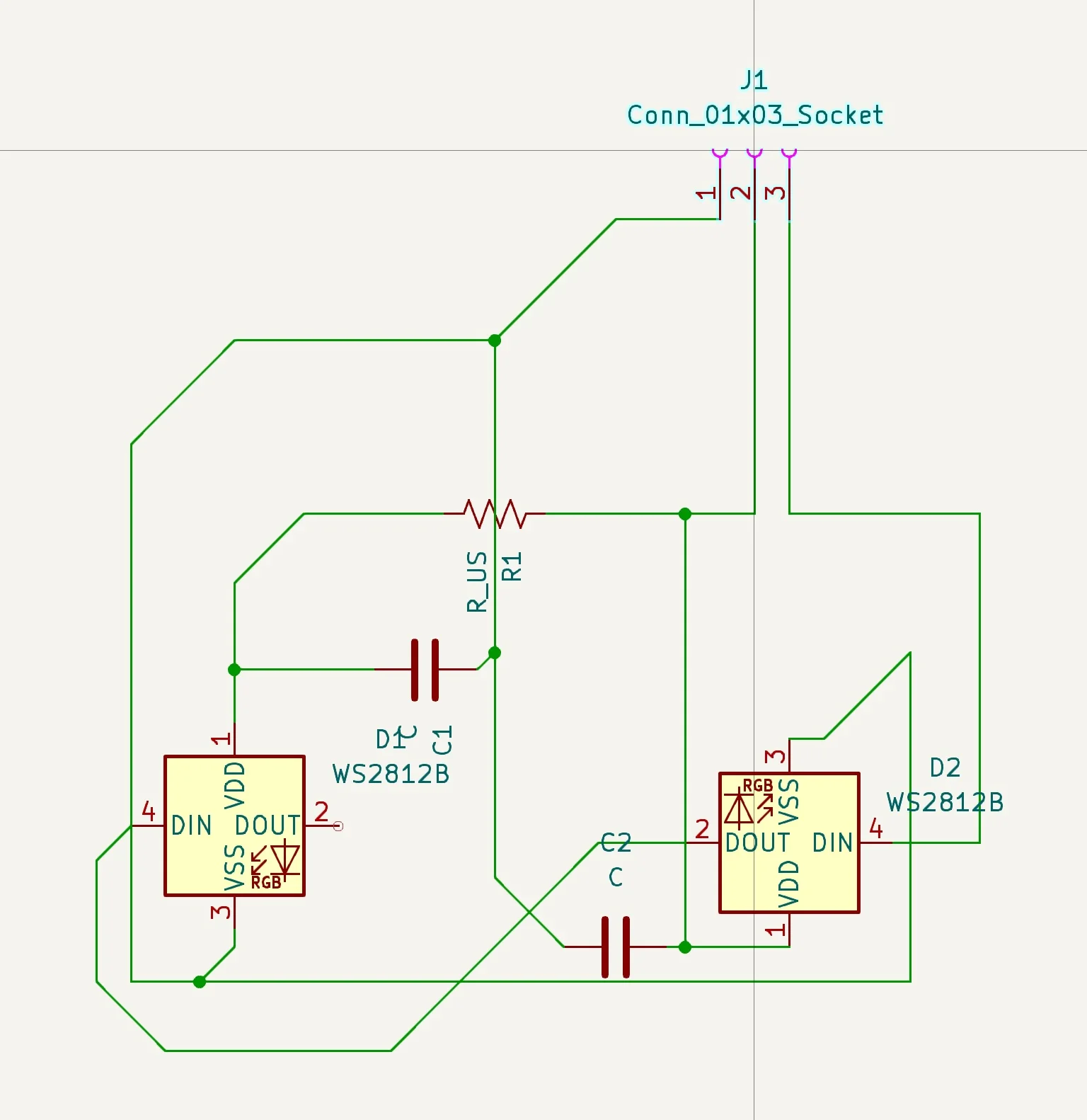

Once I can up with an idea that only included one 0 ohm resistor that served as a jumper wire.

I spoke with Nate for help, and he advised me to try using two neopixels at first.

It'd take a long time to mill, and most of the complexity is just in two neopixels.

Everything else was at scale. The challenge could be solved with just trying two neopixels.

It took me a while to come up with this idea. I had started with such a large scope.

However, it felt more mangeable now since now I was narrowing it down, and I felt

confident know what it could have looked like (at that it likely would have worked!).

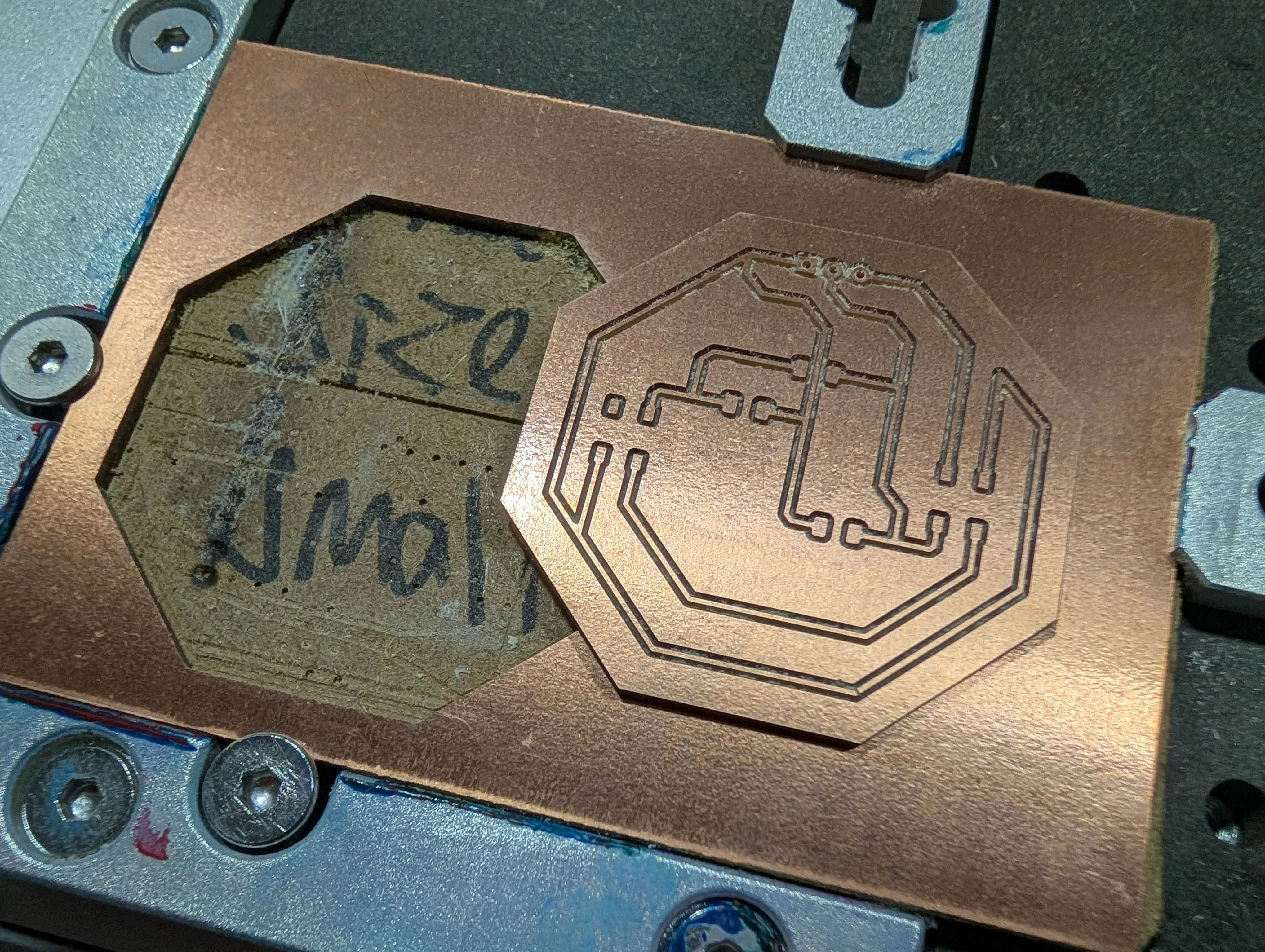

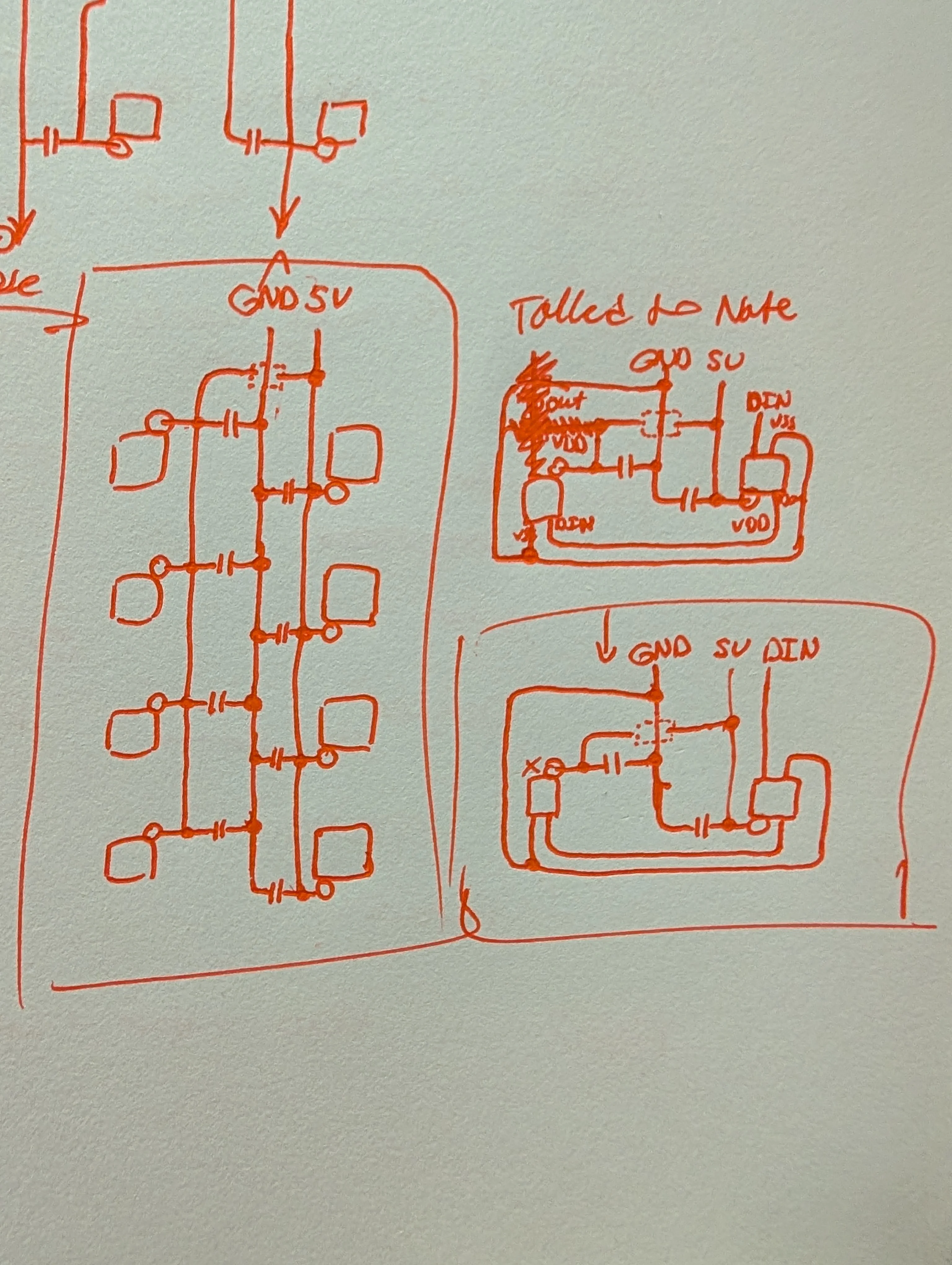

My hand-drawn wiring gave me a quick start to the schematic drawing.

It's horribly messy, but this schematic was mostly there functionally.

I needed it to assign footprints and help me design the actual PCB.

I started wiring in KiCAD following what I did on my paper.

I chose to set header pins that would attach directly to the Metro M0 Express.

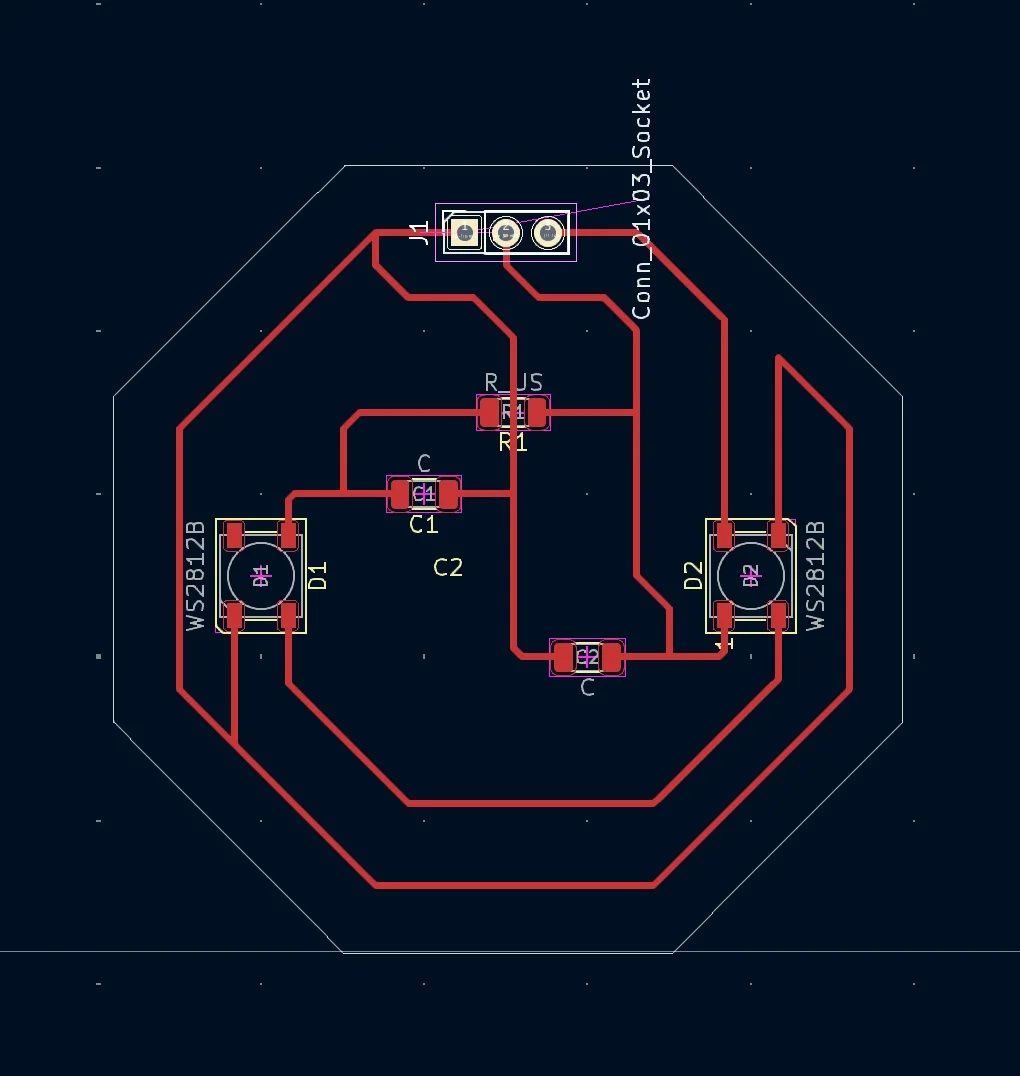

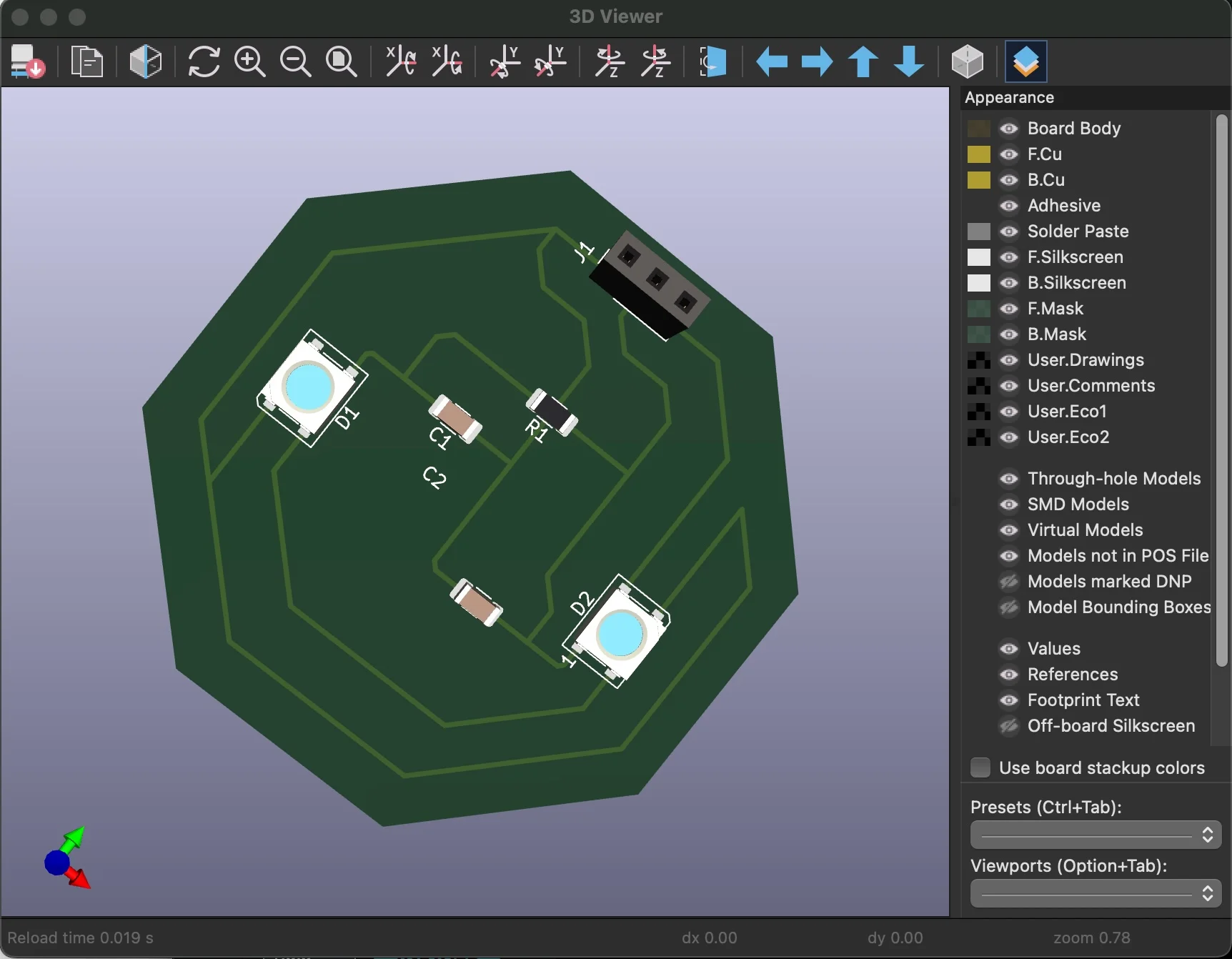

I noticed that these components could be organized one on each side.

Since most angles in KiCAD are 45º, edge cuts in the shape of an octogon seemed fitting! c:

I had a lot of help from my fellow forge community in this stage.

My MakeraCAM version prevented me from contouring my traces.

Alisa worked closely with me to convert my gerber files to g-code on her laptop.

By the time I had g-code, it was too late in the day for me to mill. I needed to go home.

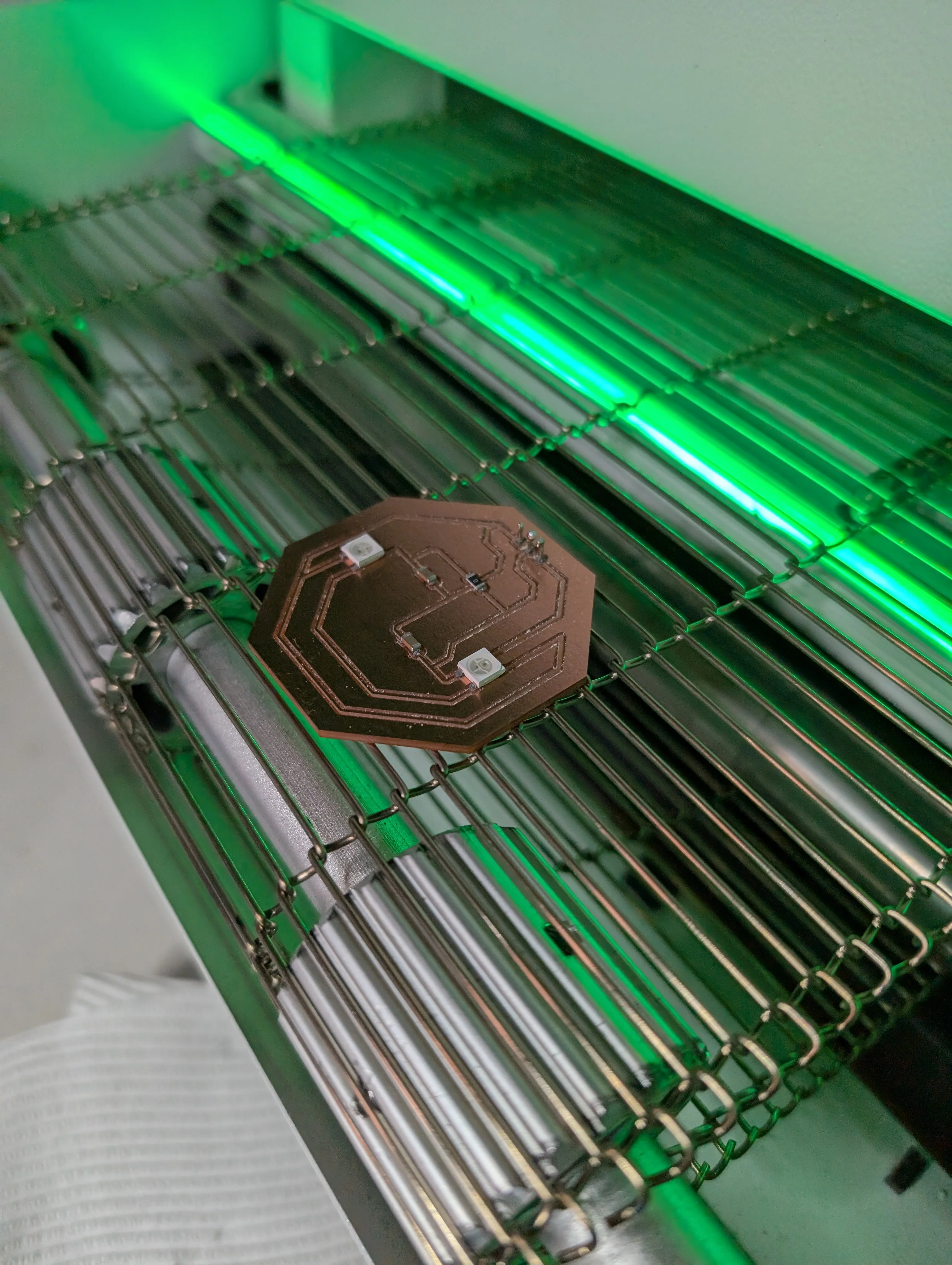

The next morning I got to the IRL before 8am to get started.

I ran into a problem when I hesitated and stopped the carvera in the middle of it switching bits.

An ATC