Since I fell behind last week, I decided to focus on making something simple

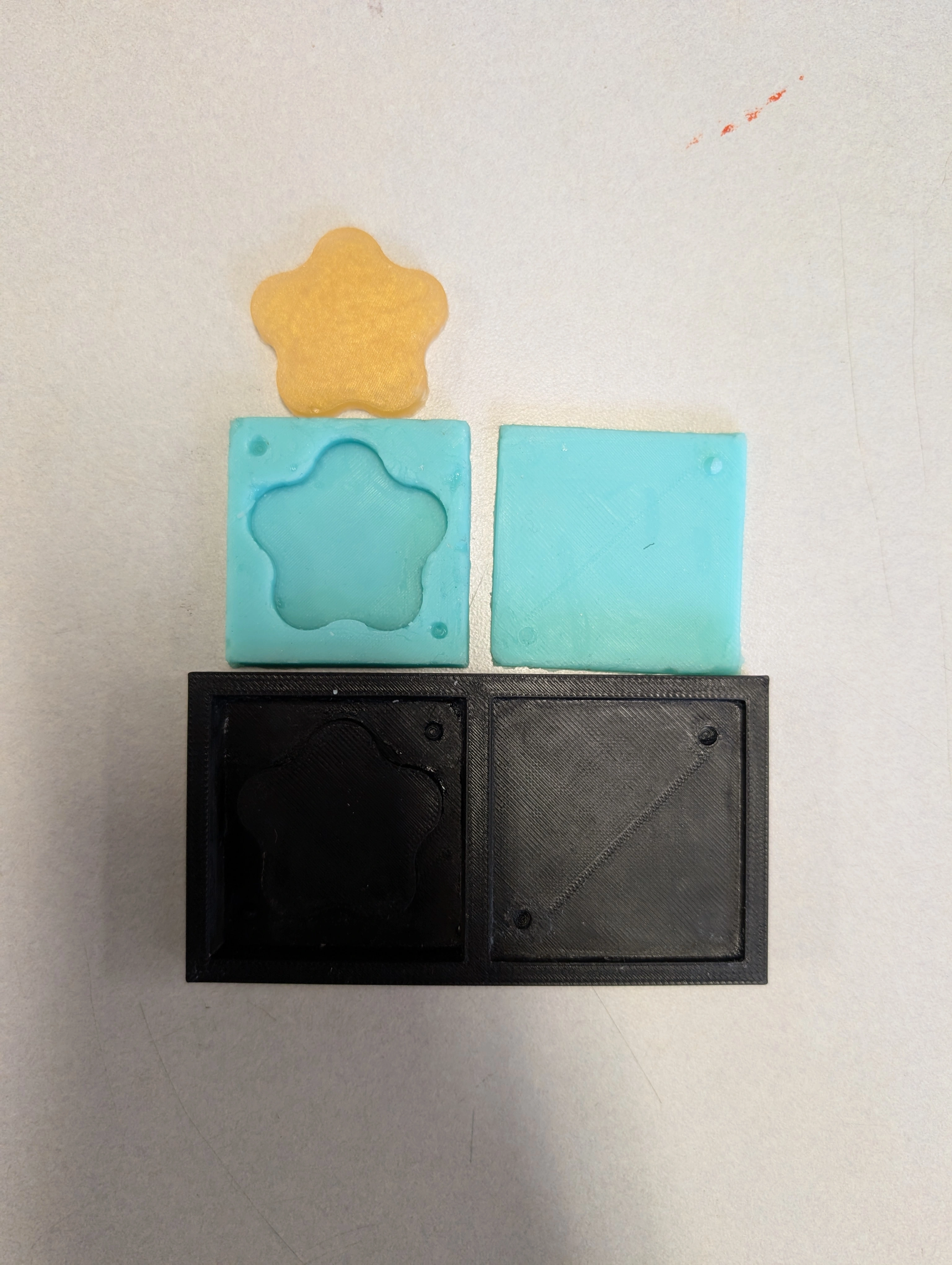

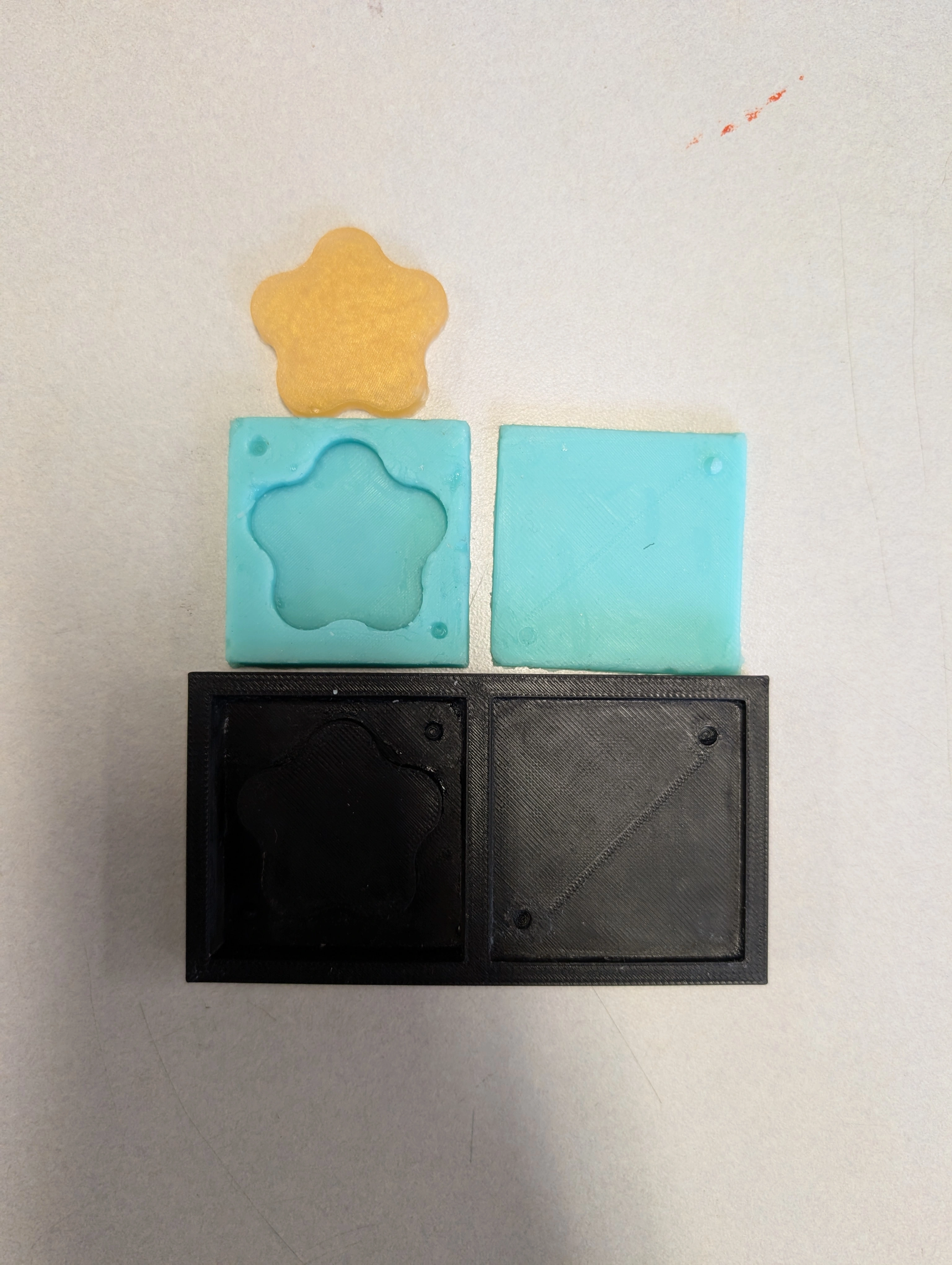

I ended up going for a star shape.

Hannah really helped me this week! :D

She's a staff member at the IRL2

She informed me of what to do to create the mold and resin cast.

I started by 3D printing a PLA positive for the star.

In the IRL2, I combined parts A and B of the silicon.

Using a scale, I measured 10g each and stirred the liquid silicon.

I poured the silicon into the PLA.

Then I put it into a chamber in the IRL2, and then filled it with pressurized air.

This silicon mold cured for 24 hours.

The next day, I returned to the IRL2, took out the mold (negative), and cleaned it.

There was Aluminite (resin) and pigments in the IRL2.

I sifted through the pigments and found gold.

There and then, I decided this star must be made of gold.

A little bit of gold pigment and the alumnite combined.

I filled the sillicon mold with the colored resin.

Once again, I placed it into the pressurized chamber.

This time I left it for 48 hours over MLK holiday weekend.

When I returned, the star was complete!

Hannah was a huge help, I was very happy with the outcome! :D

Thank you Hannah!