The goal for this week was to CNC a 3D mold and then cast it.

My first idea was to do a spikeball. So I modeled it.

However, I realized that it would be impossible to CNC because of the over hangs the spikes caused.

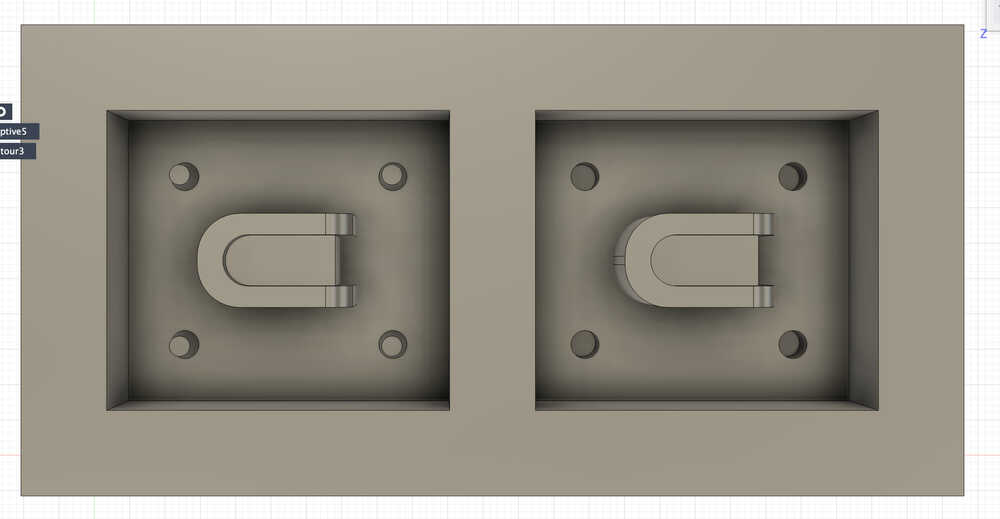

I then spent time making a simple model of the Bible.

Couldn't add text because that was too small for the bit on the XCarve.

Now here is where the problems appeared.

I proceded to spend HOURS trying to make the model work with Fusions CAM.

But no matter what I did...something would always be wrong with the end result

and I didn't know enough of Fusion Manufacture to fix it.

I had more results making this meme than I did trying to CAM in Fusion.

So after lots of failing I quit any hope I had and decided to 3D print my spike ball.

This gave me freedom from the agony of Fusion and my chains were broken.

I went with the spikeball in the end because I already had that modeled in Fusion.

For the 3D model I used 0.08mm High Quality layer height and it turned out pretty good.

I wanted to fill up my 3D model with OOMOO 25 but all of them were solid.

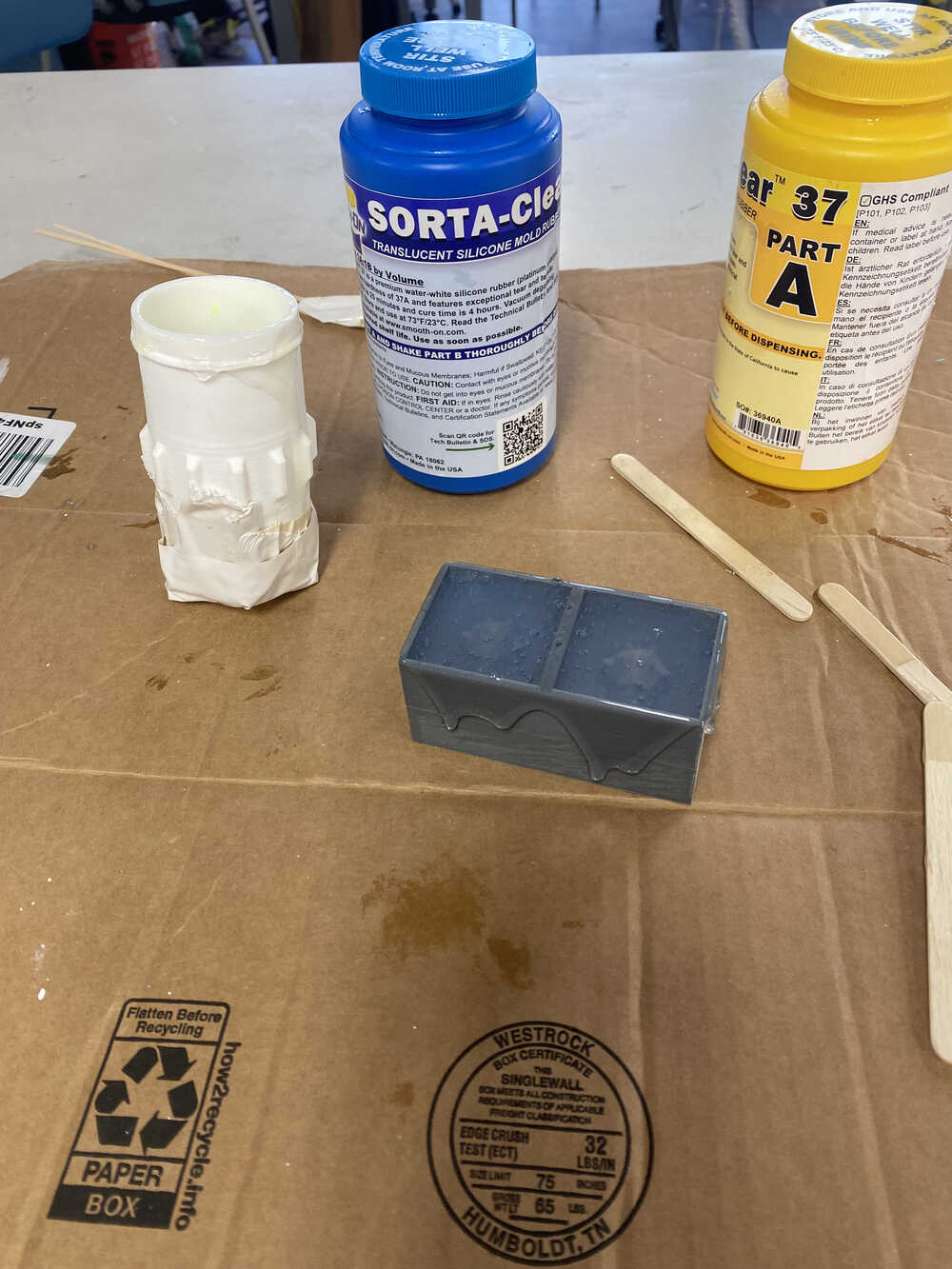

Instead, I filled up my 3D model with Sorta Clear 37.

I used the cup Luke made out of PVC. It worked great!

To get the bubbles out I used the air compressor by turning it on so it could vibrate.

When the air compressor was full I emptied the air and started the process again.

I feel this method got some of the bubbles out but a lot it was still trapped in the mold.

Overall, the project was a failure

but I think I got a little more familiar with Fusions UX for their CAM software.