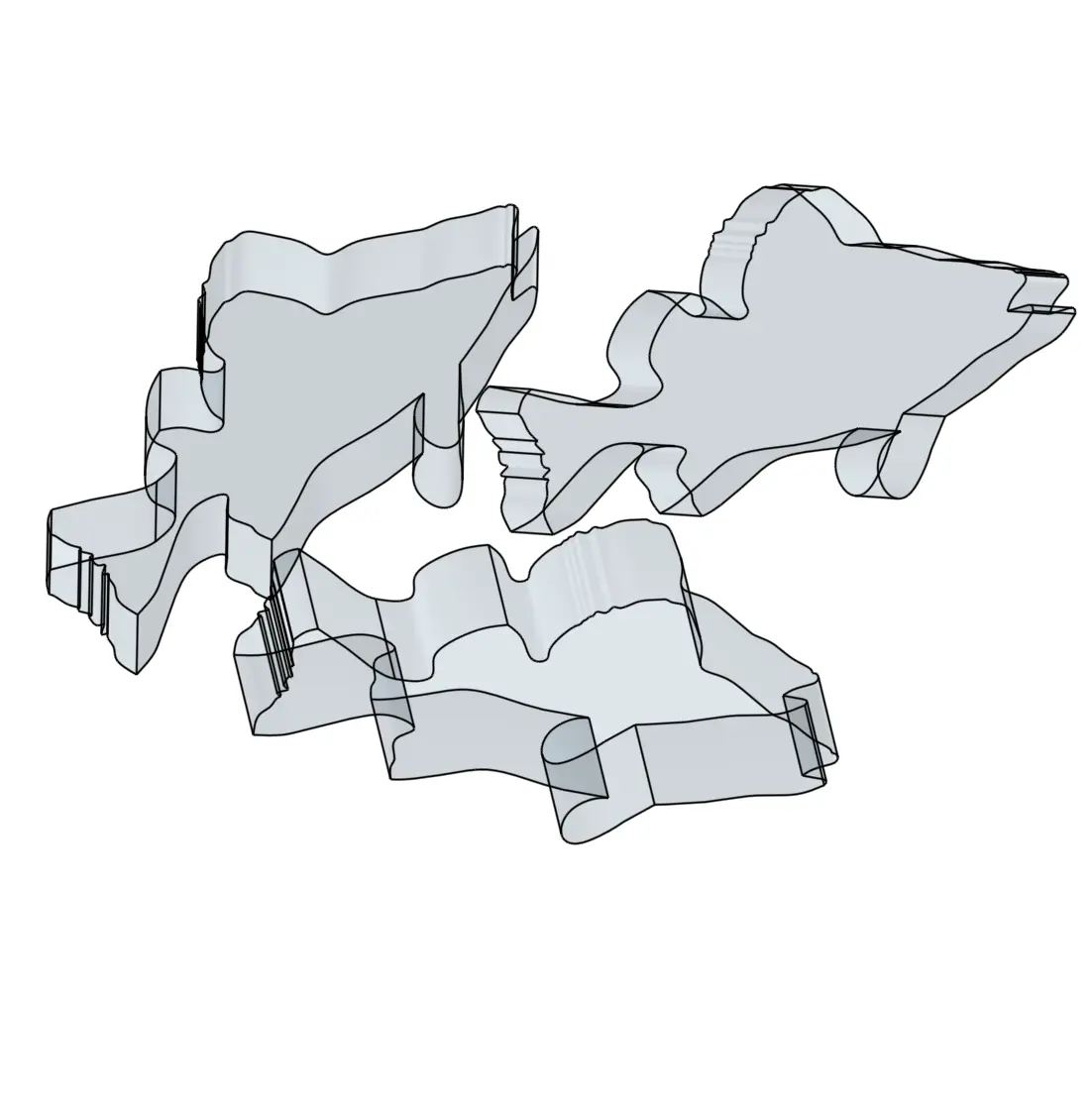

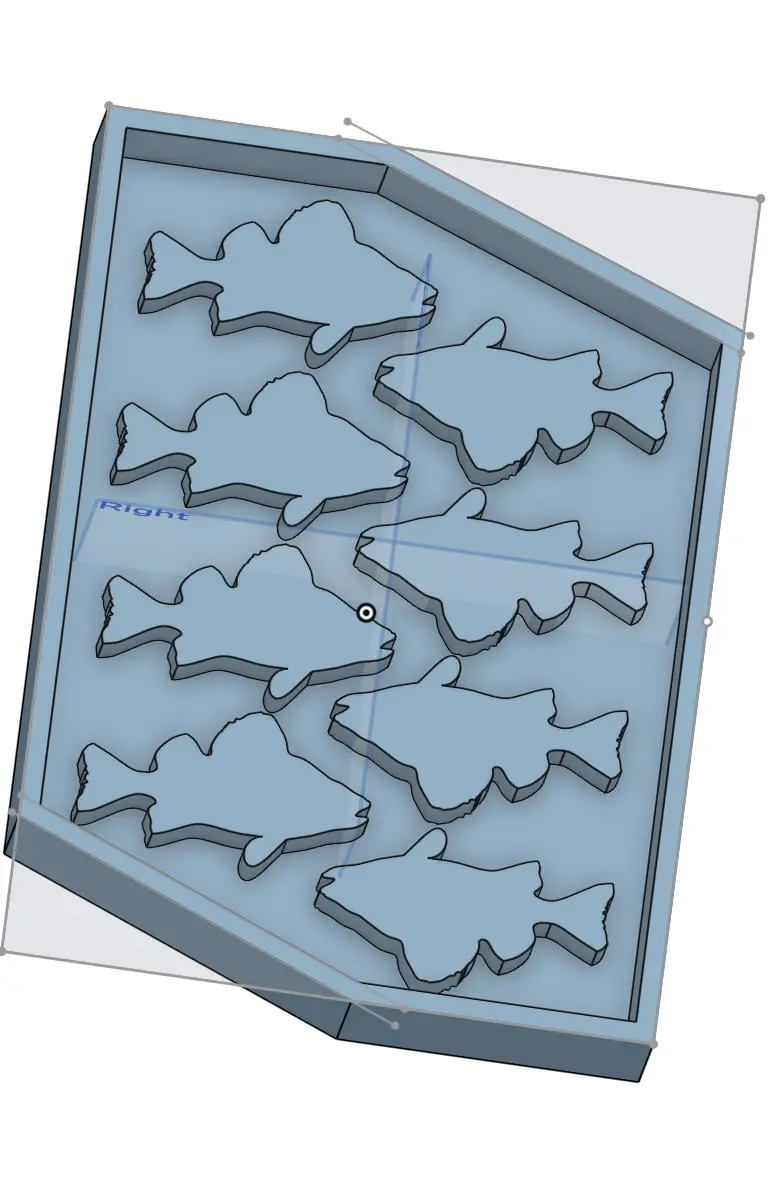

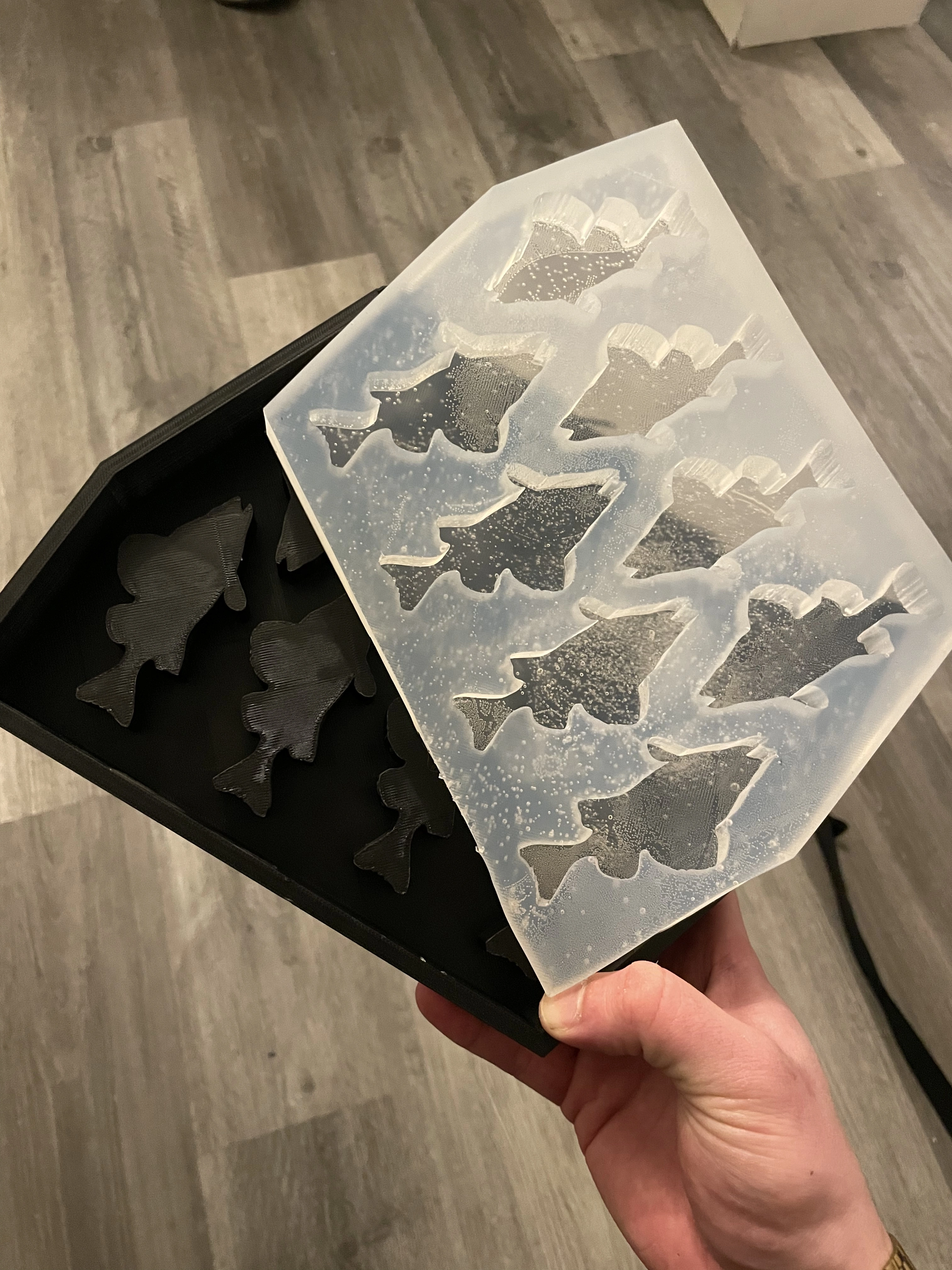

Week 12's assignment was to create a mold. I decided to make an ice cube tray using SORTA-Clear 037: a food safe silicone. Rather than using a wax block and the CNC, I opted for FDM printing. SORTA-Clear 037 is very flexible after curing, meaning layer lines shouldn't be an issue. Despite this, I still sanded down the obvious layers and seams. Next, I cleaned the print with isopropyl alcohol and applied mold release angent. Once the mold was prepped, I began mixing the silicone. I placed the 1:1 mixture in a vaccum chamber and pulled 40 PSI. This helped with most of the bubbles, but the mixture was so viscous that a lot remained. After pouring the mixture into the print, I created a simple jig from scrap wood and an orbital sander to vibrate the mold, hopefully releasing more bubbles. This worked with larger bubbles, but was not super sucsessful. I then tried to eliminate bubbles with a heat gun, but this only seemed to warp the top surface without releasing air. The pot life had passed and I figured I got all the air out that I could, so I left the mold to cure for 24 hours. The next day, I was able to remove the sillicone from the print, and use it to create fish shaped ice cubes.