3D PRINTING

This weeks assignment was to make something 3d printed that cannot be made through subtractive

manufacutring.

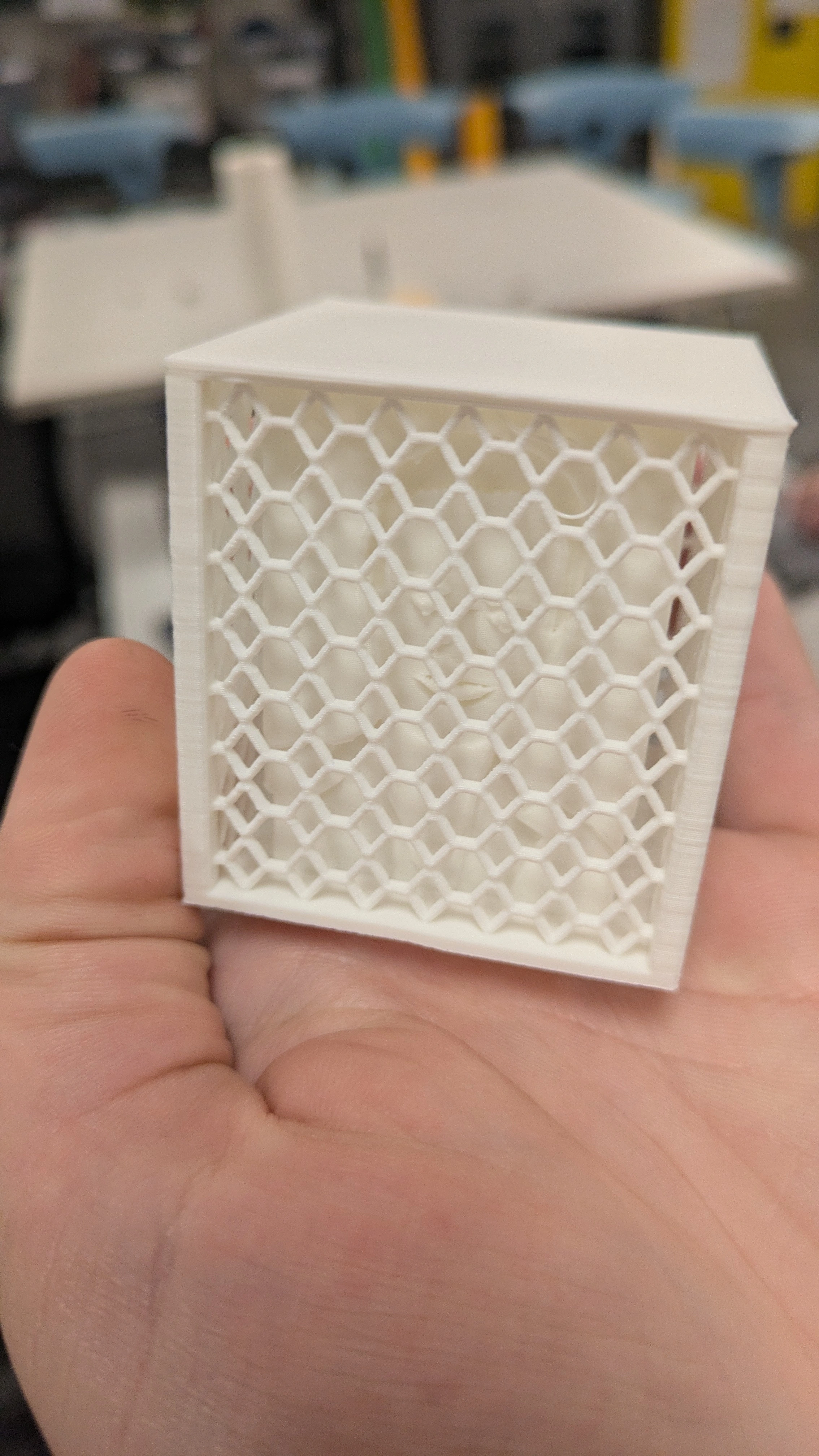

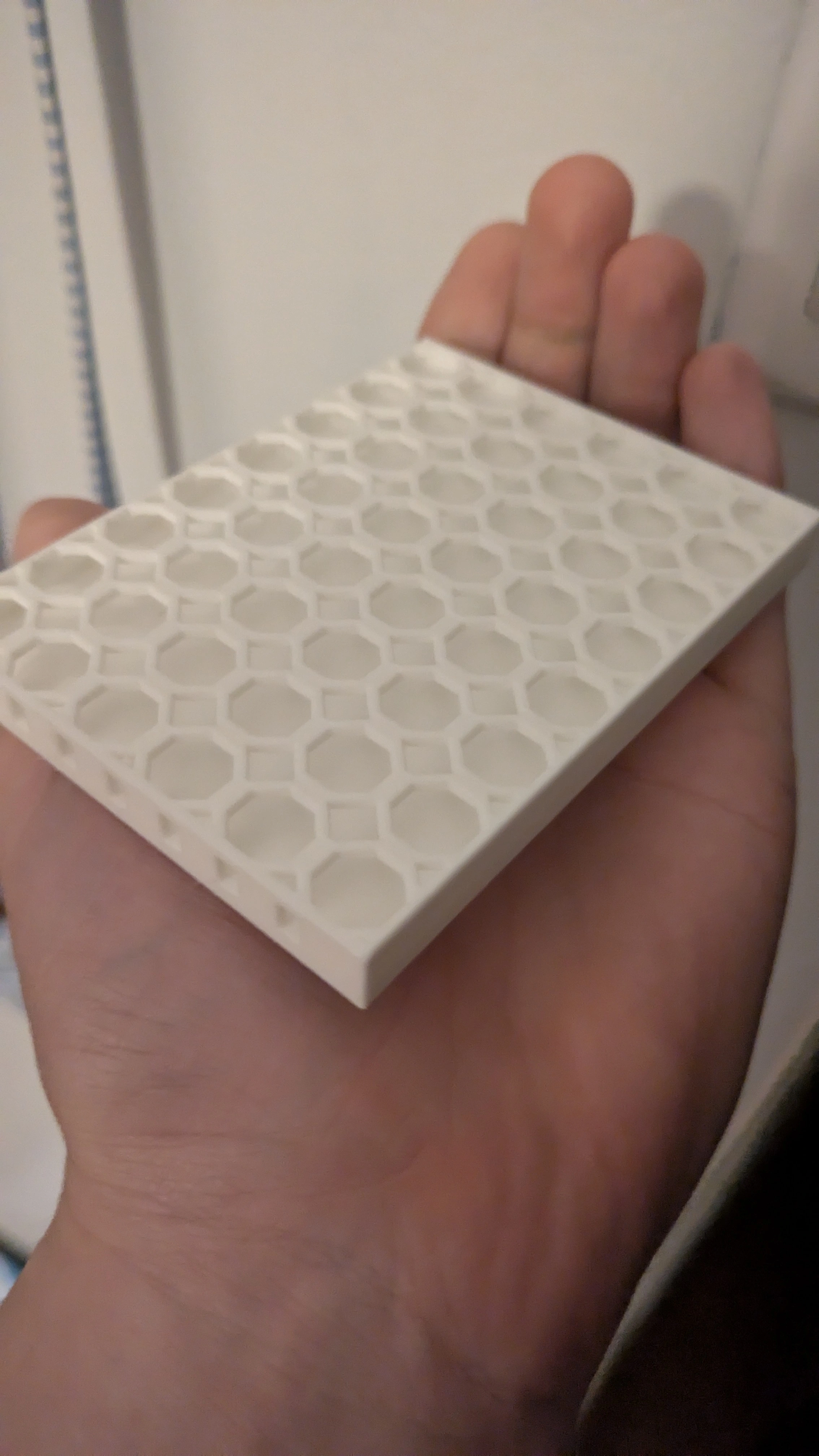

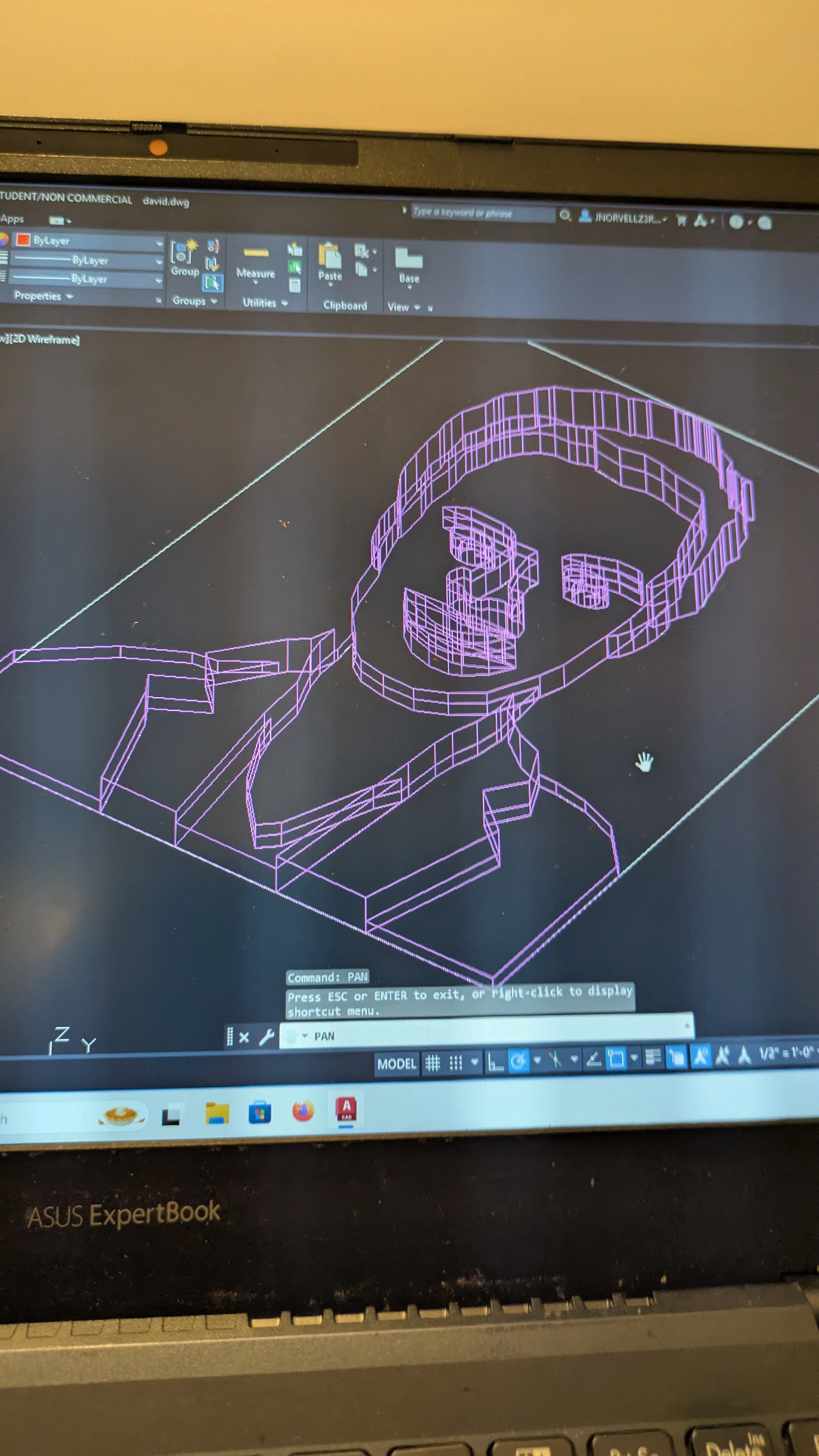

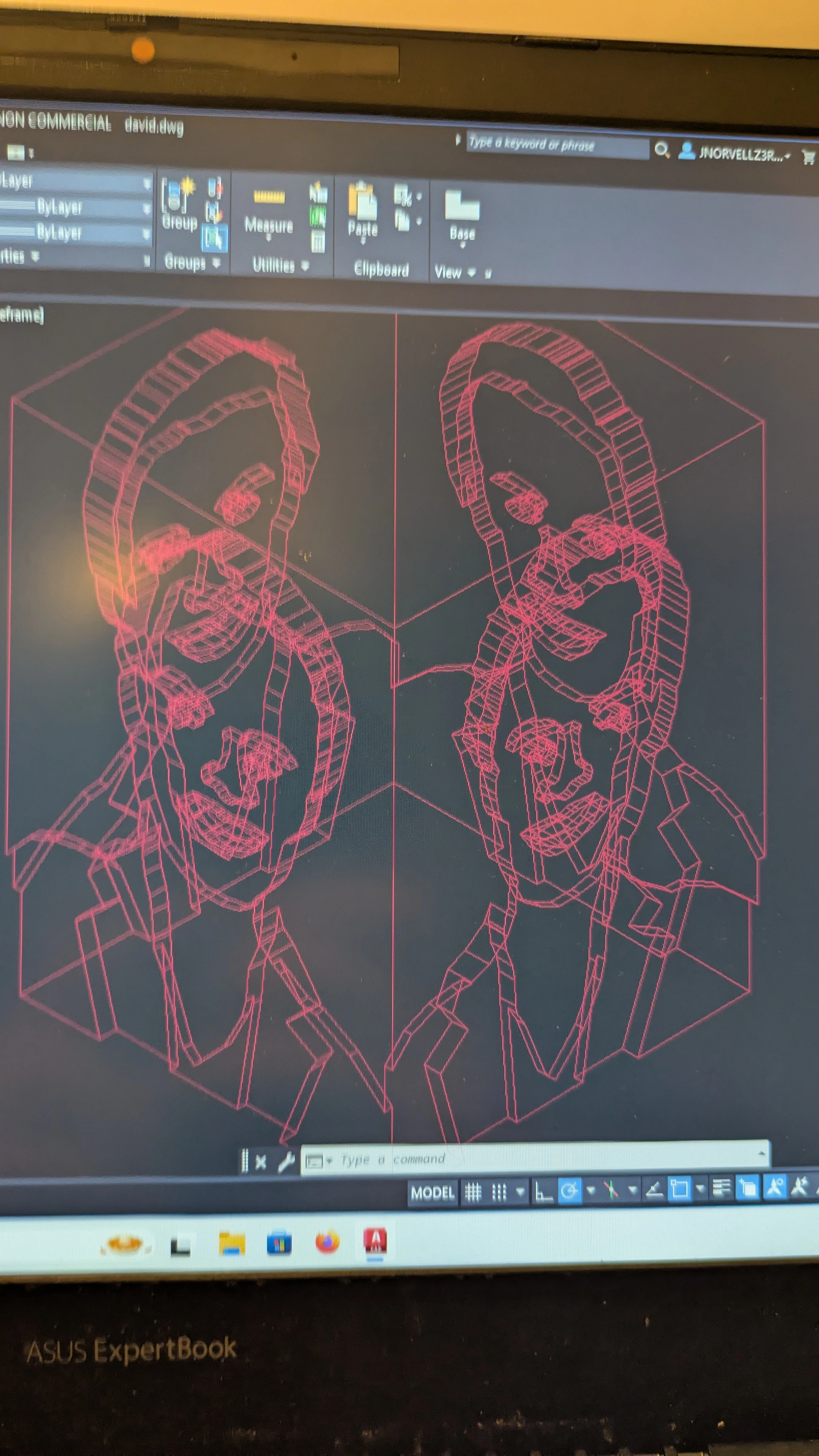

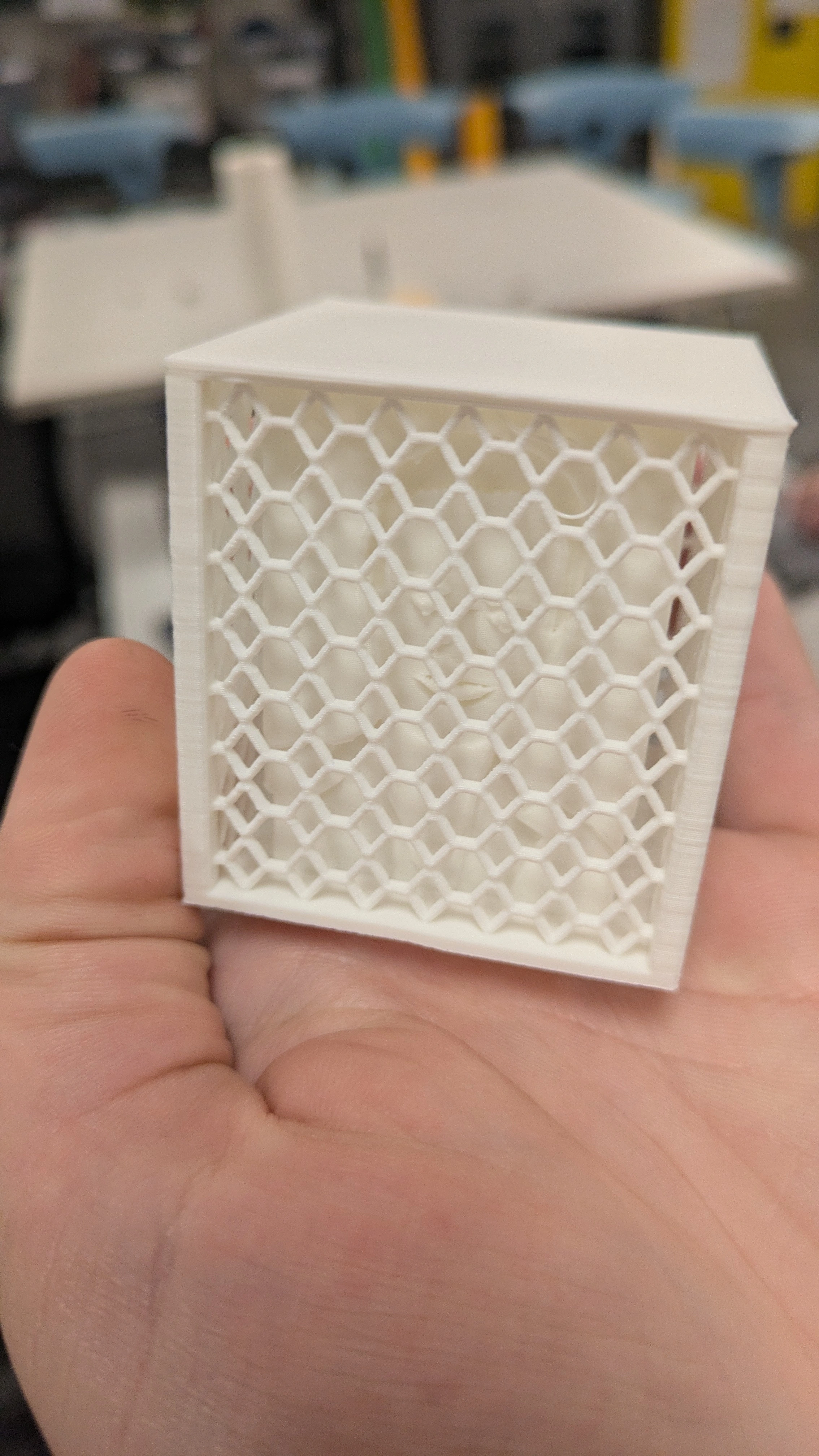

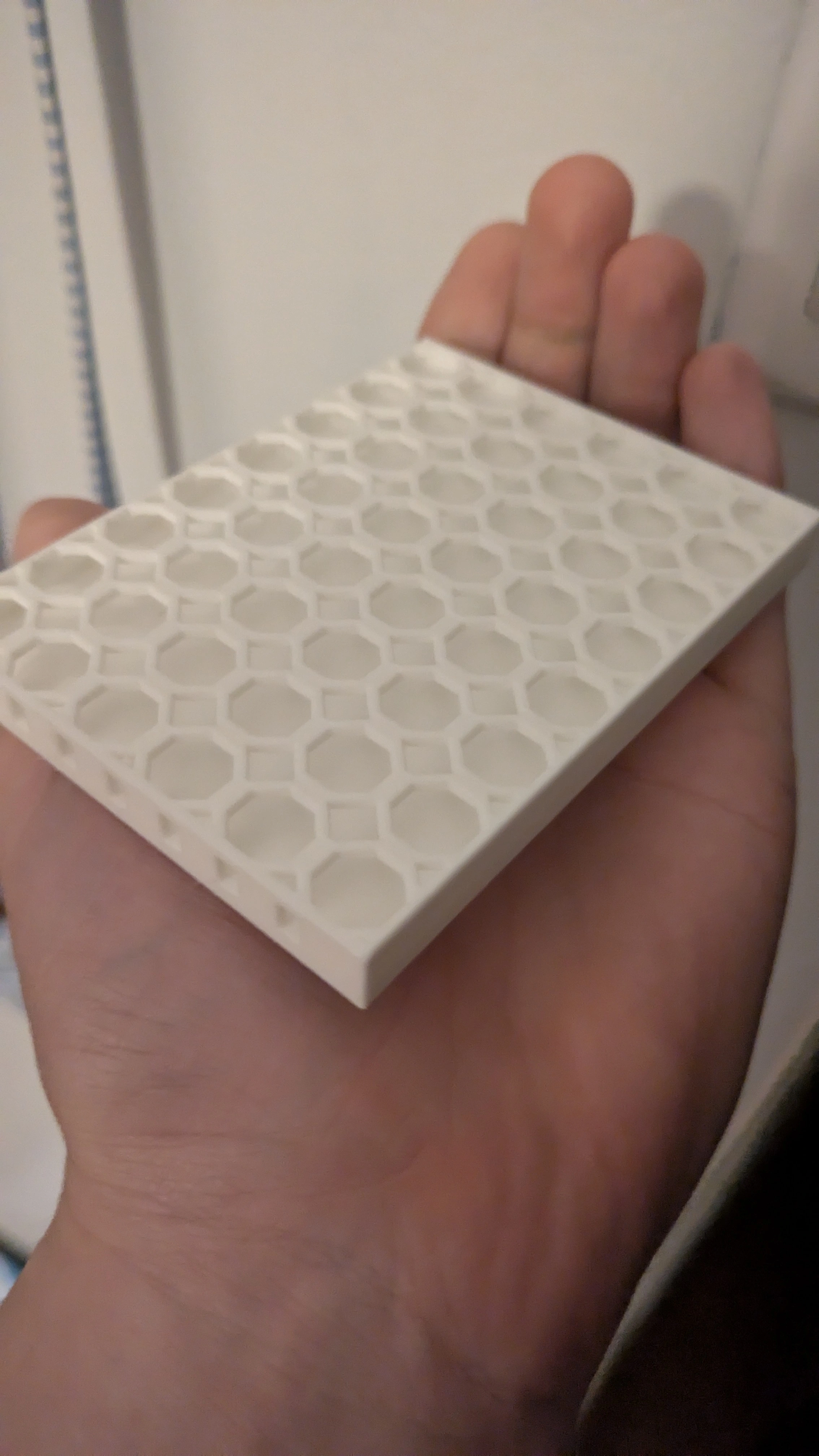

For this I had 2 ideas that I made and 3d printed, firstly a little soap holder for my shower that lets

water drain from it

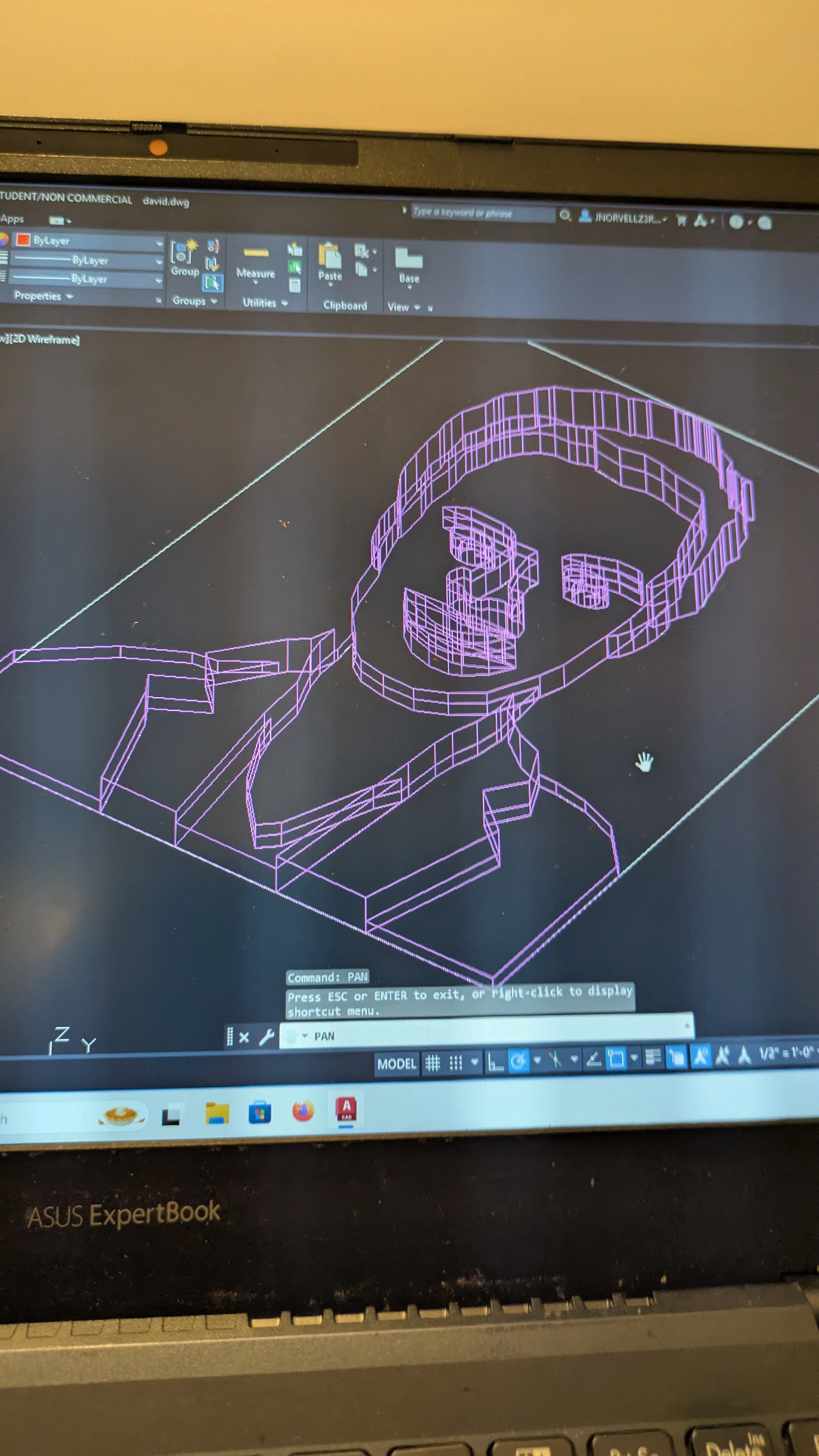

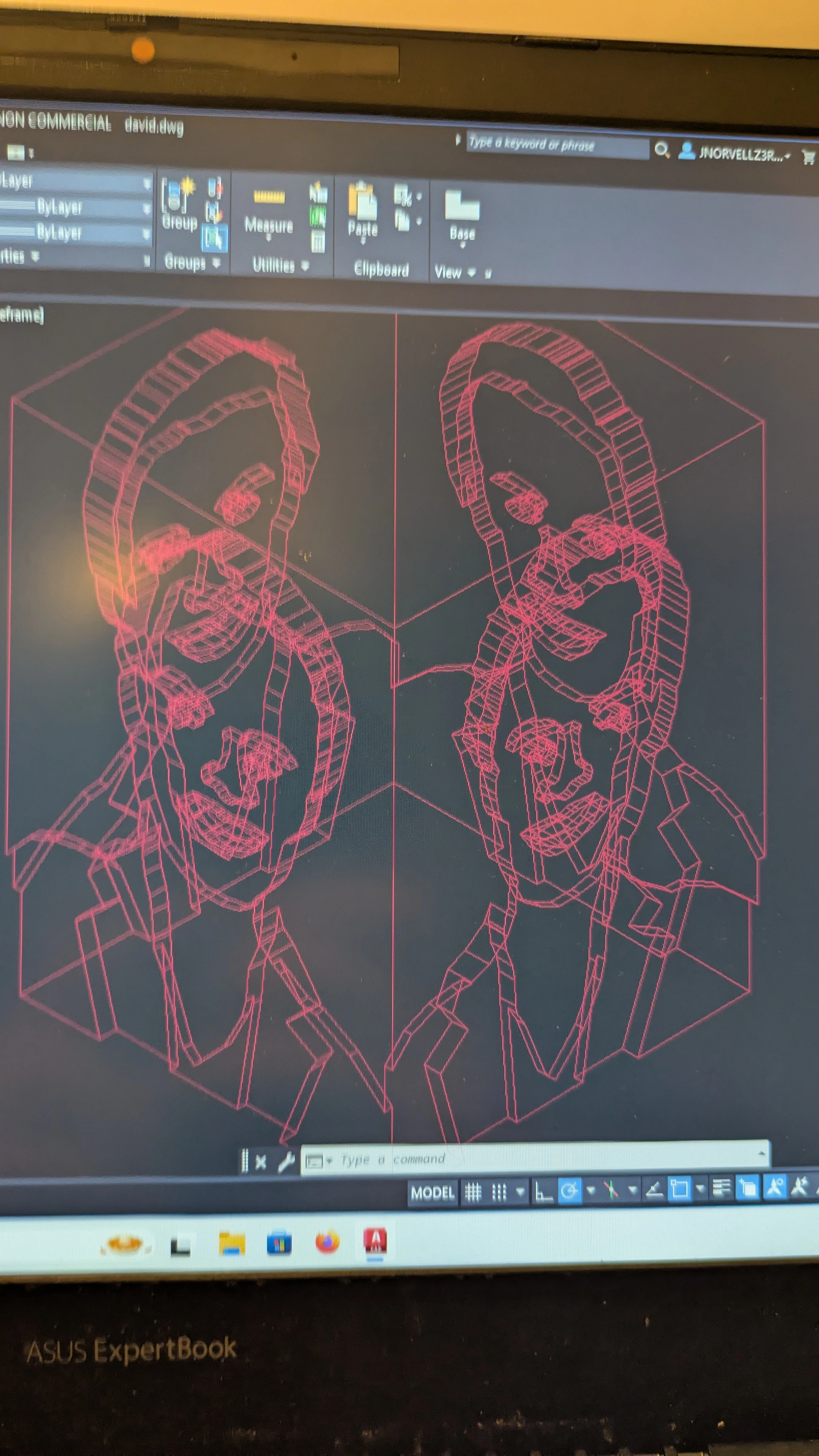

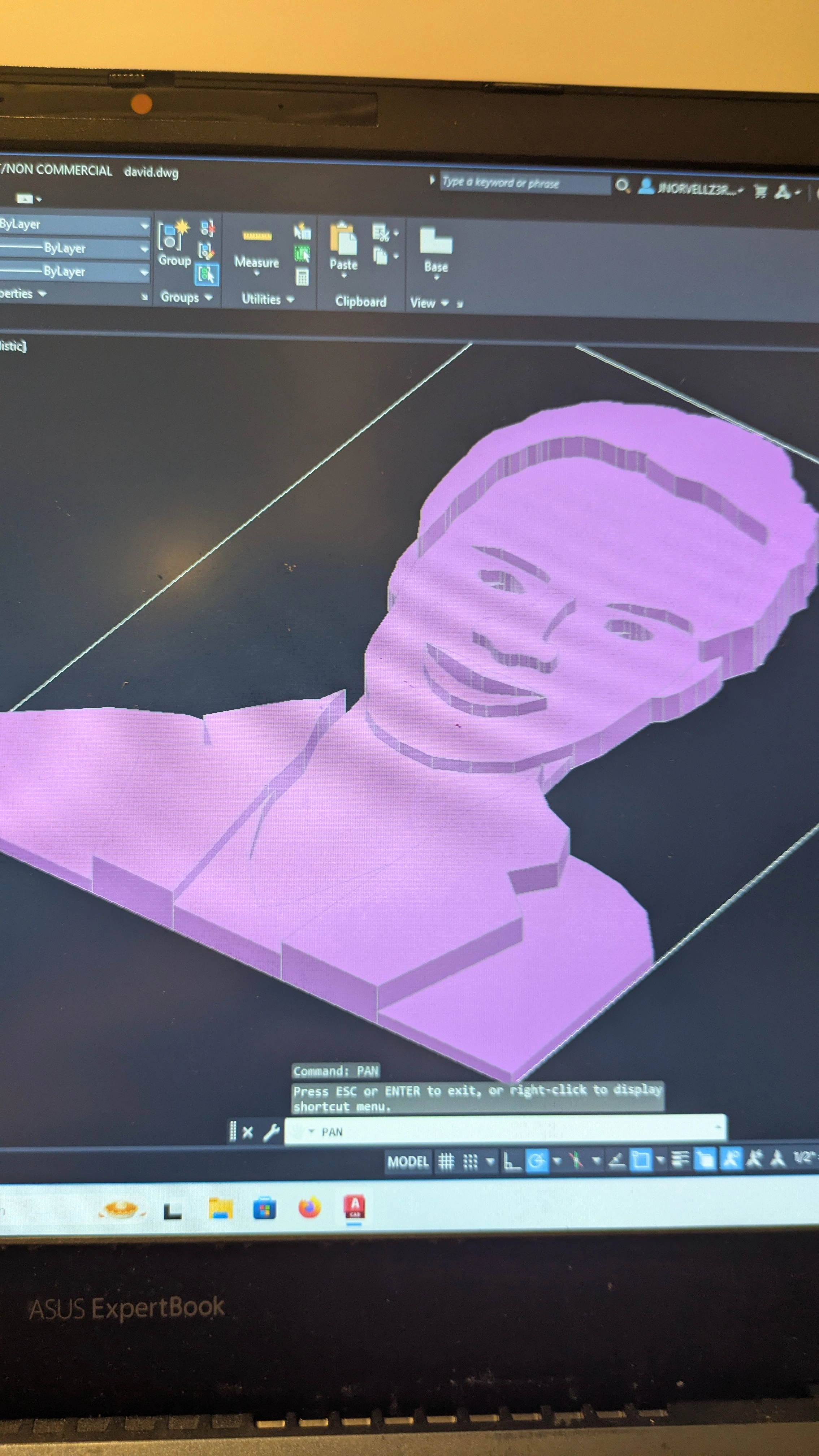

as well as a milk crate type cage with davids face inside of it.

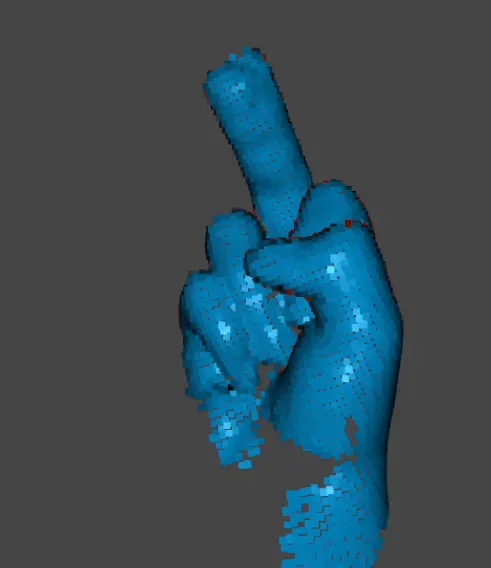

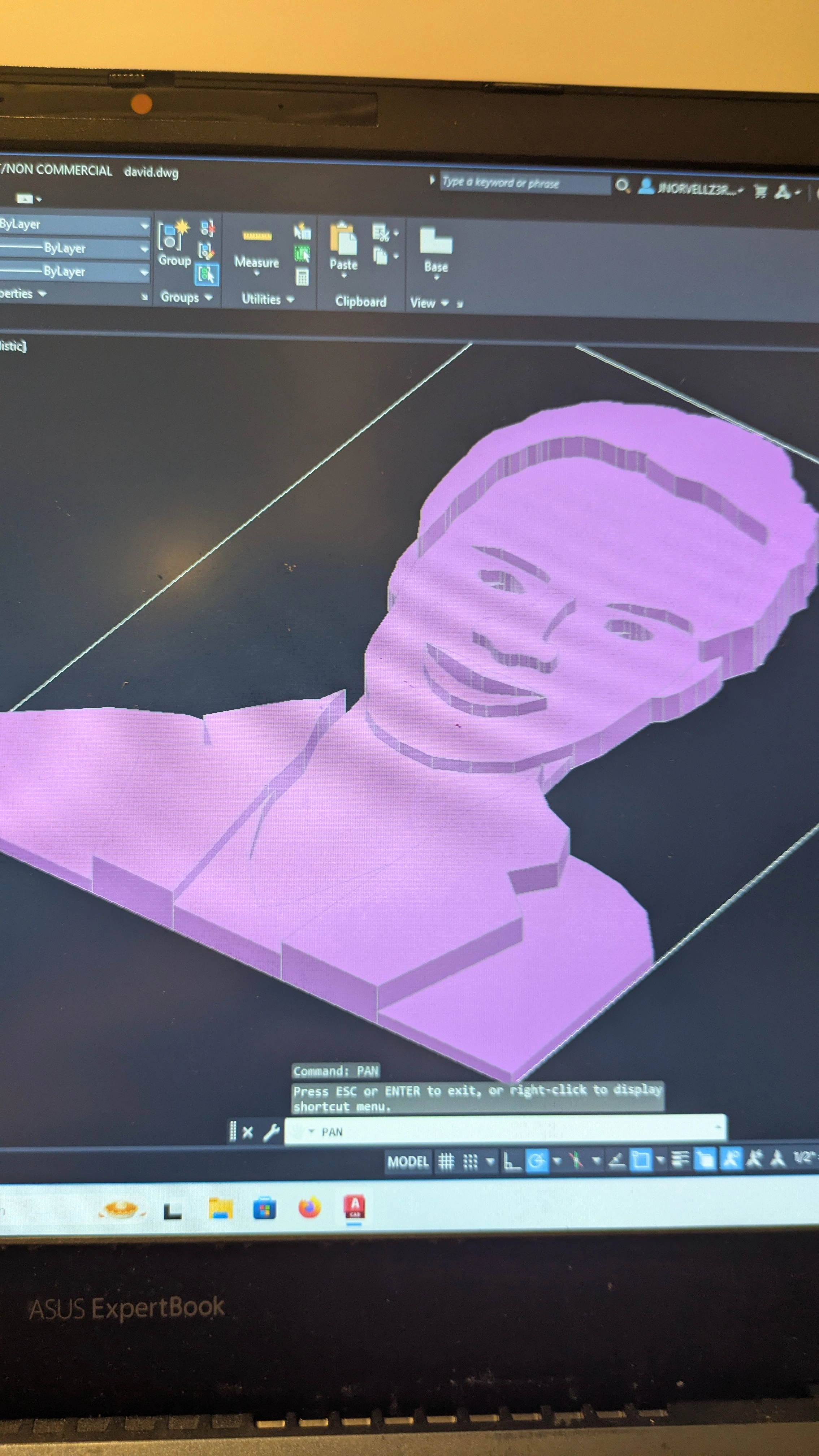

When initally coming up with the idea for a cage with david inside of it I indended to take the 3d scan of

his face and make a full 3d david that is internal.

This posed 2 issues, editing a mesh is extremely tedious and I really did not want to go through that for

the bit so I dont krill myself,

AutoCAD (the CAD progam given to us by god) does not really like importing meshes: therefore I do not like

meshes.

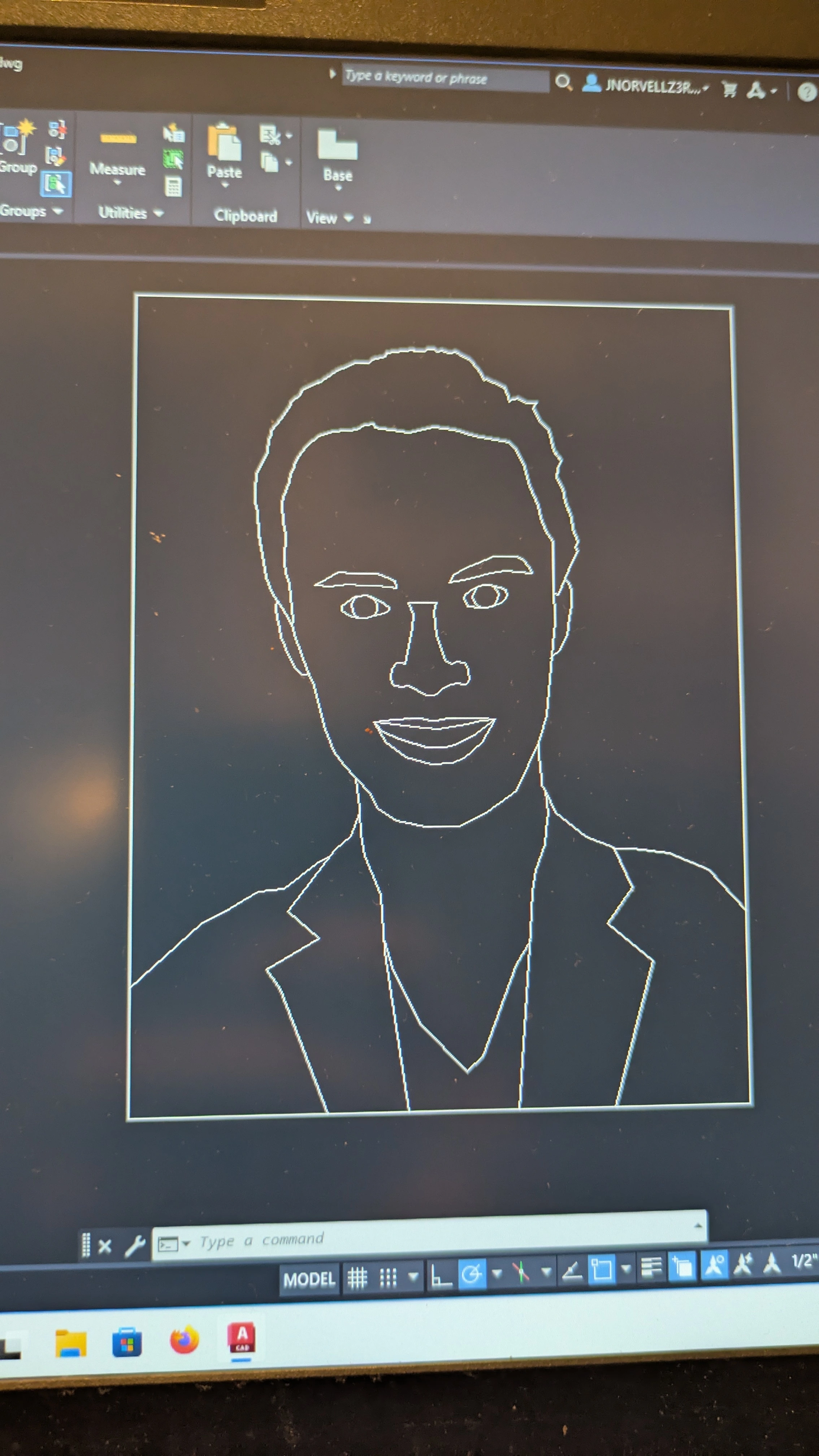

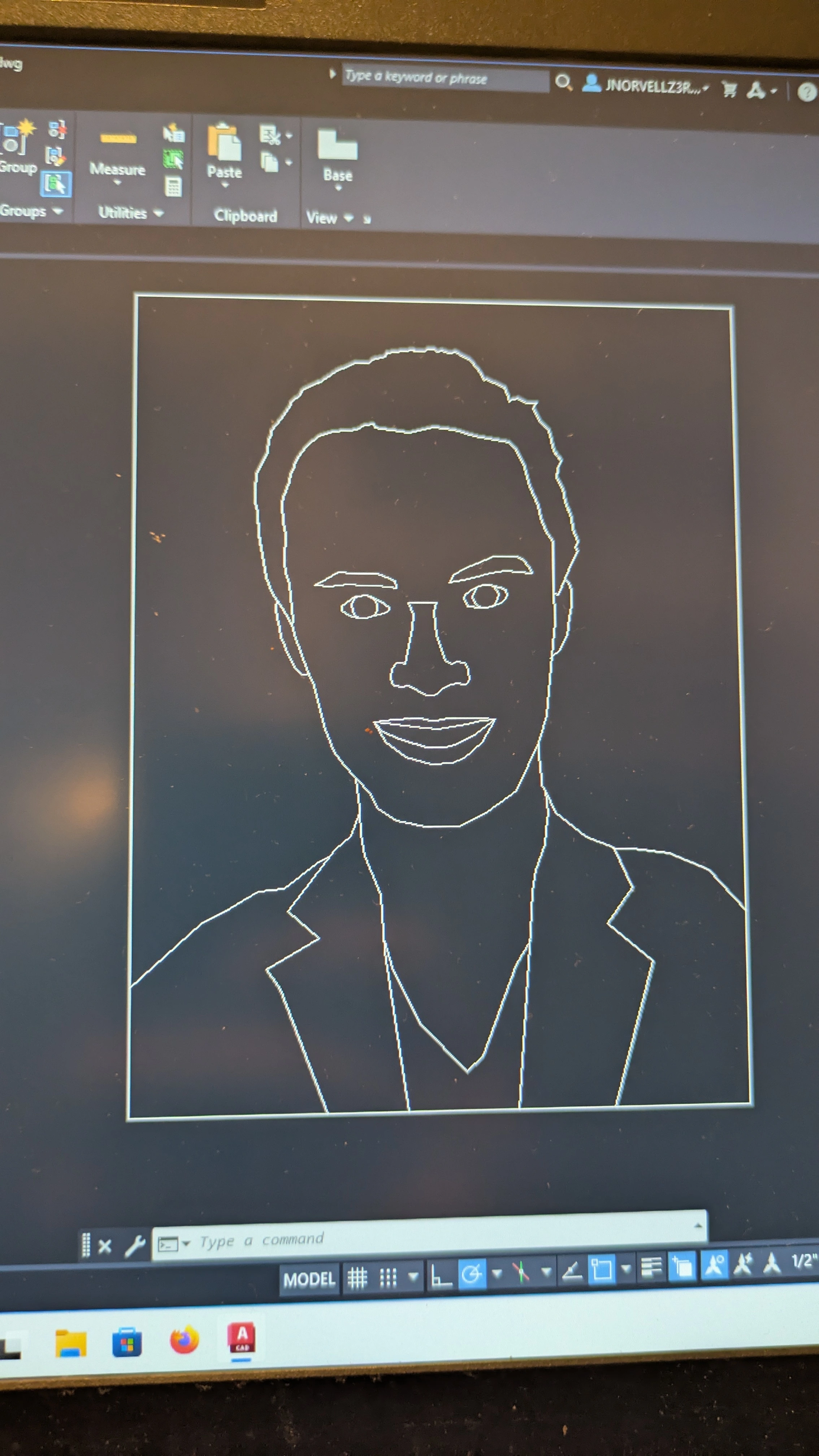

inital sketches

david sketches

final products

Otherstuff

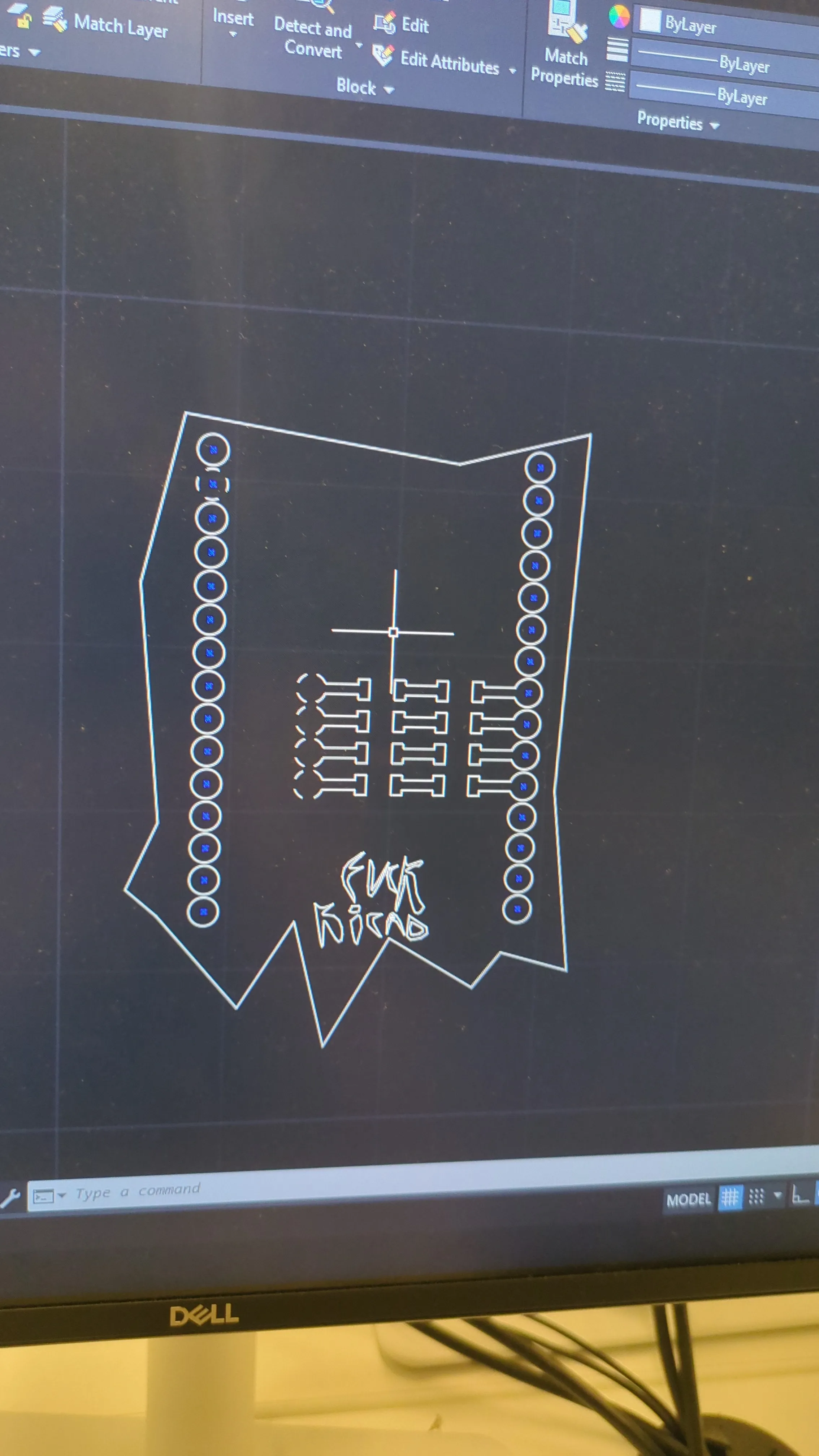

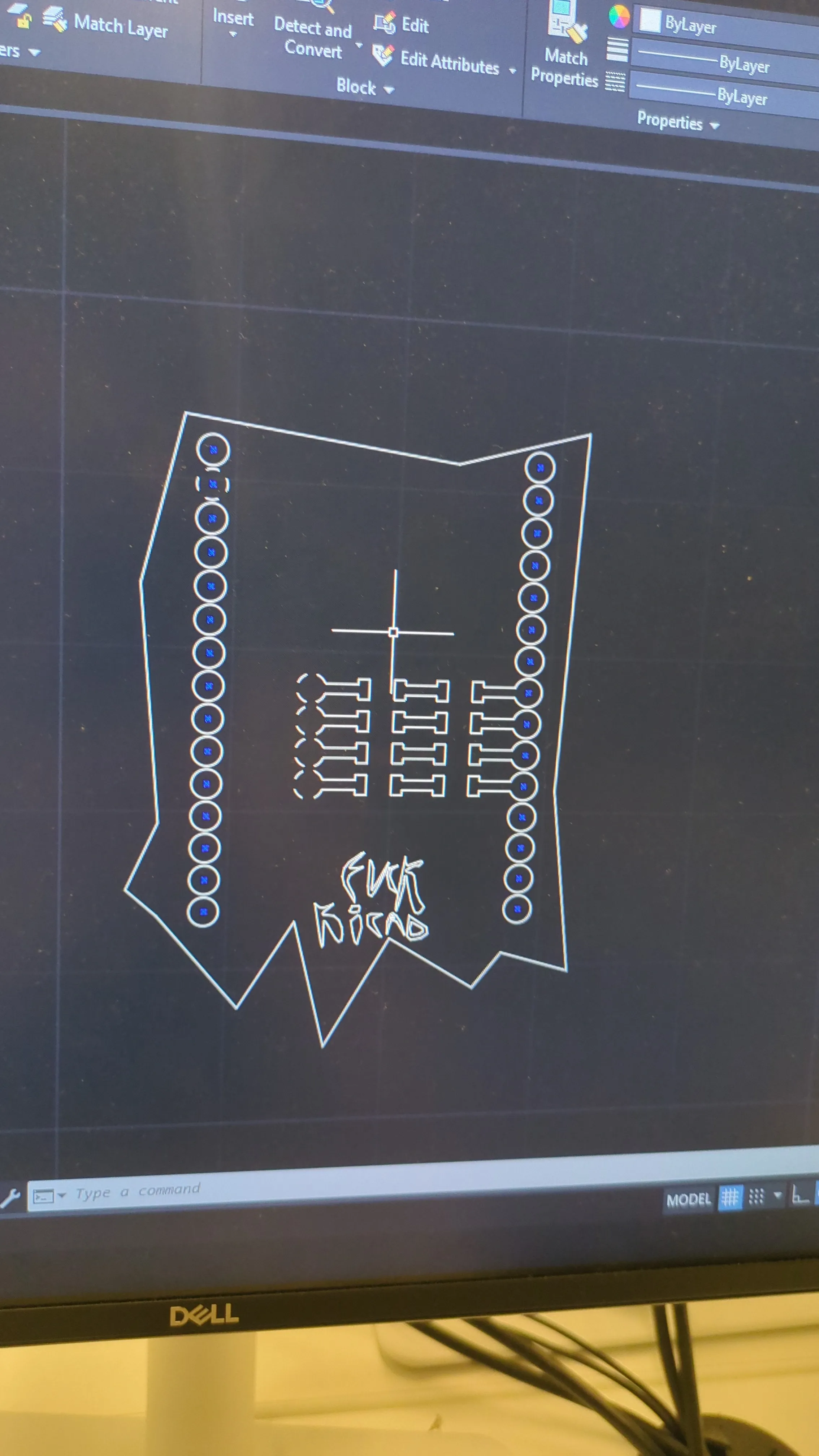

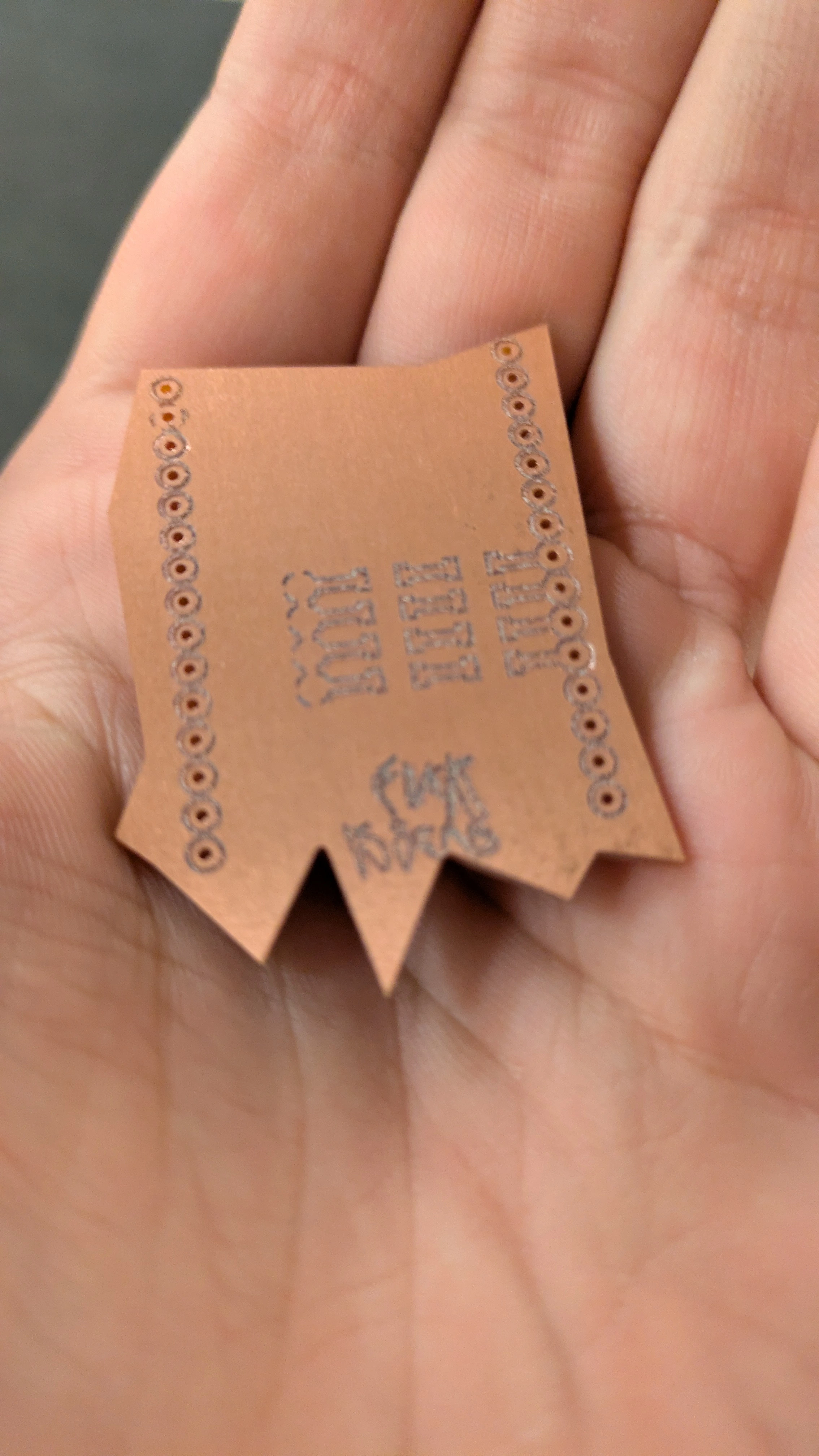

Additonally time was spent this week attempting to fix my broken PCB from last week.

The main problem with last weeks board was a poor and rushed solder job and artifacts left from transfering

from kicad over to makera.

To fix makera problems I remade the board in AutoCAD (my beloved), this took less time than making it in

kicad and left greater control over my traces.

The one issue with this method is transfering a dwg into other files which doesnt preserve scale so making a

large rectangle that is used for scale because I would rather die than use metric units.

also kicad is a bitch program made for those too weak to use autocad like a real man

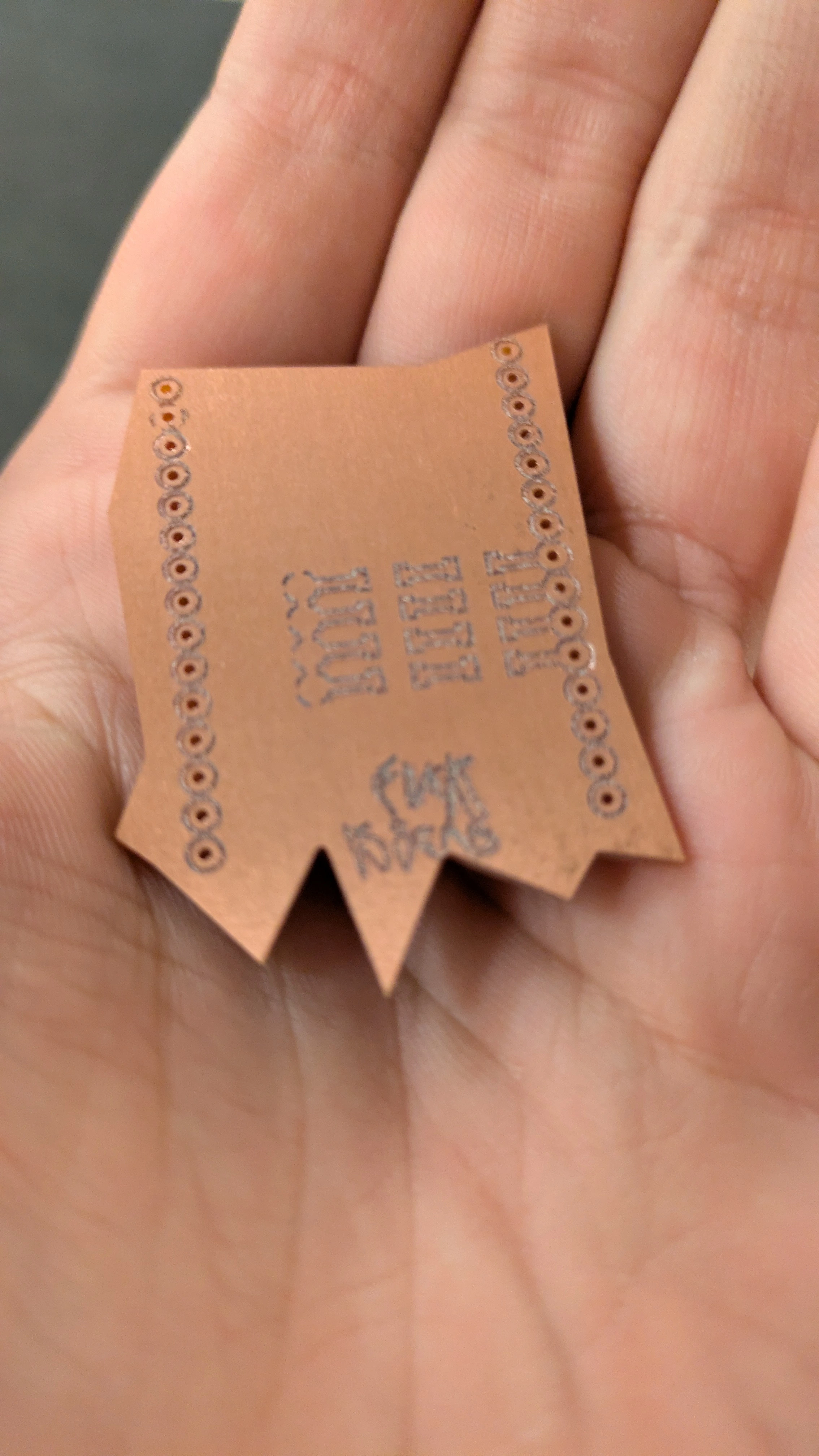

New ESP32 sheild

So erm, I might have shorted this board on all the traces from some really poorly done soldering job, more importantly this design proves that both kicad sucks

and that autocad is objectively a better program.

Again though it was a great chance for more experience with the carvera and it means that I feel much more confindent in using it.

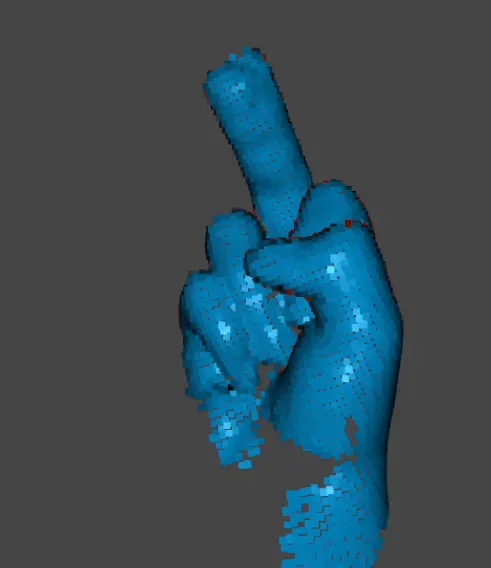

I also 3d scaned somethin