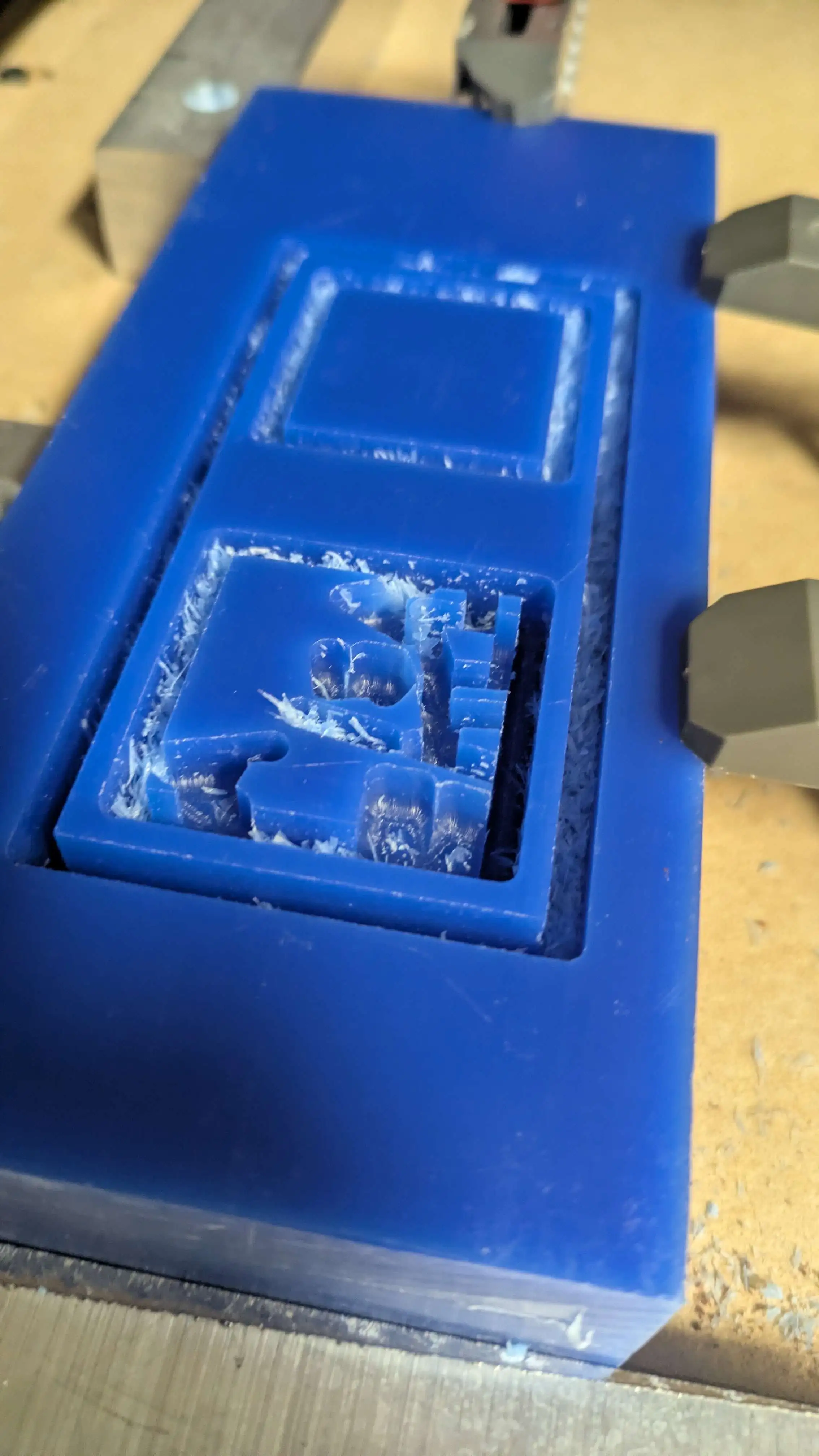

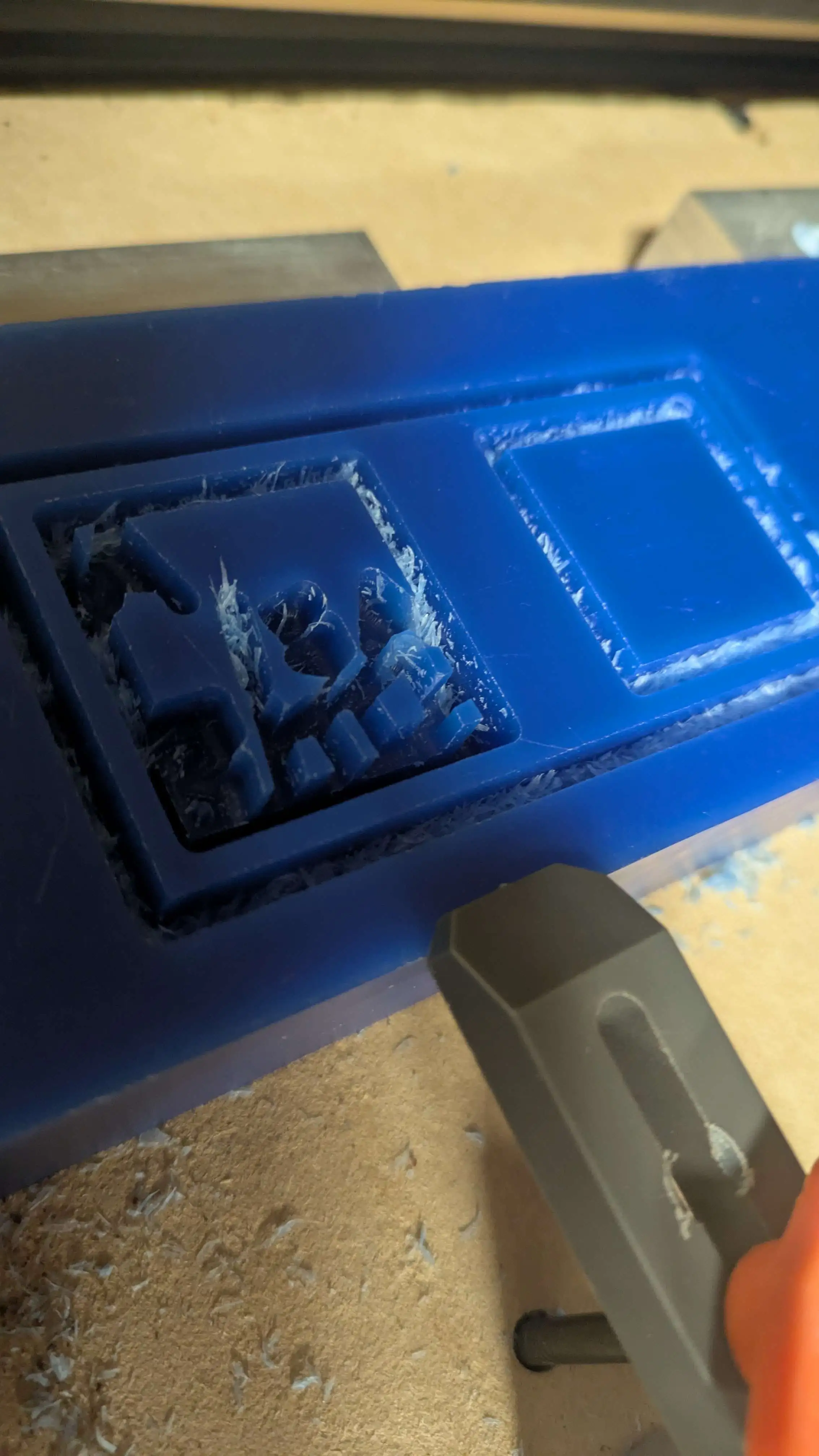

First I tried using easle invenables website to create gcode, due to the depth of the finishing cut being so deep it felt unsafe to continue so we switched to use vcarve to make gcode

Following this I used vcarve to generate tool paths but this had issues where I forgot about bit diameter and lost a lot of detail following this and a lack of time i switched to my fail back and made a 3d printed mold

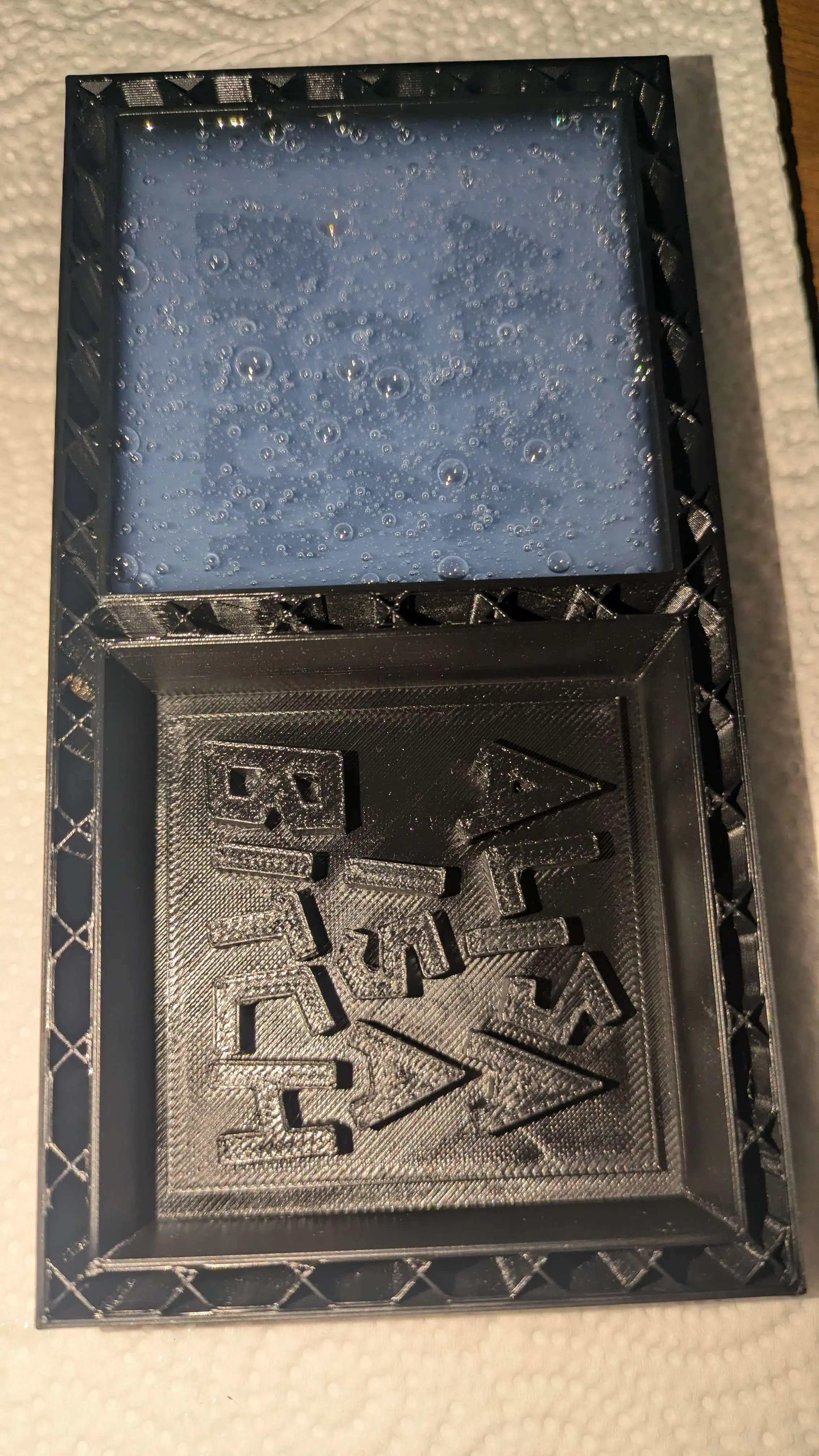

with limited time I look the mold sprayed a bunch of mold release on it, this worked quite well and the mold mostly worked, i brought this home and left it to cure for a few hours it never fully cured and i took it out too early so it had cuts but otherwise total success

here is the final mold and it worked really well I was just too rushed to take it out of the mold but otherwise total sucess